Table of Contents

Introduction

This blog will explore the significance of PSM incident investigation and process safety incident investigation in ensuring workplace safety and how these practices contribute to a safer working environment.

Process safety management is a systematic approach designed to prevent and mitigate process safety incidents in industries involving hazardous processes. Process safety incidents encompass a range of strategies, policies, and practices aimed at safeguarding personnel, the environment, and assets from potential harm. PSM incident investigation is crucial in identifying and managing hazards, ensuring operational integrity, and minimizing the likelihood of catastrophic events in high-risk industries such as oil and gas, chemical manufacturing, and pharmaceuticals.

Implementing robust process safety incident investigation and analysis processes within process safety management can help organizations effectively identify root causes, learn from incidents, and develop proactive measures to prevent future occurrences.

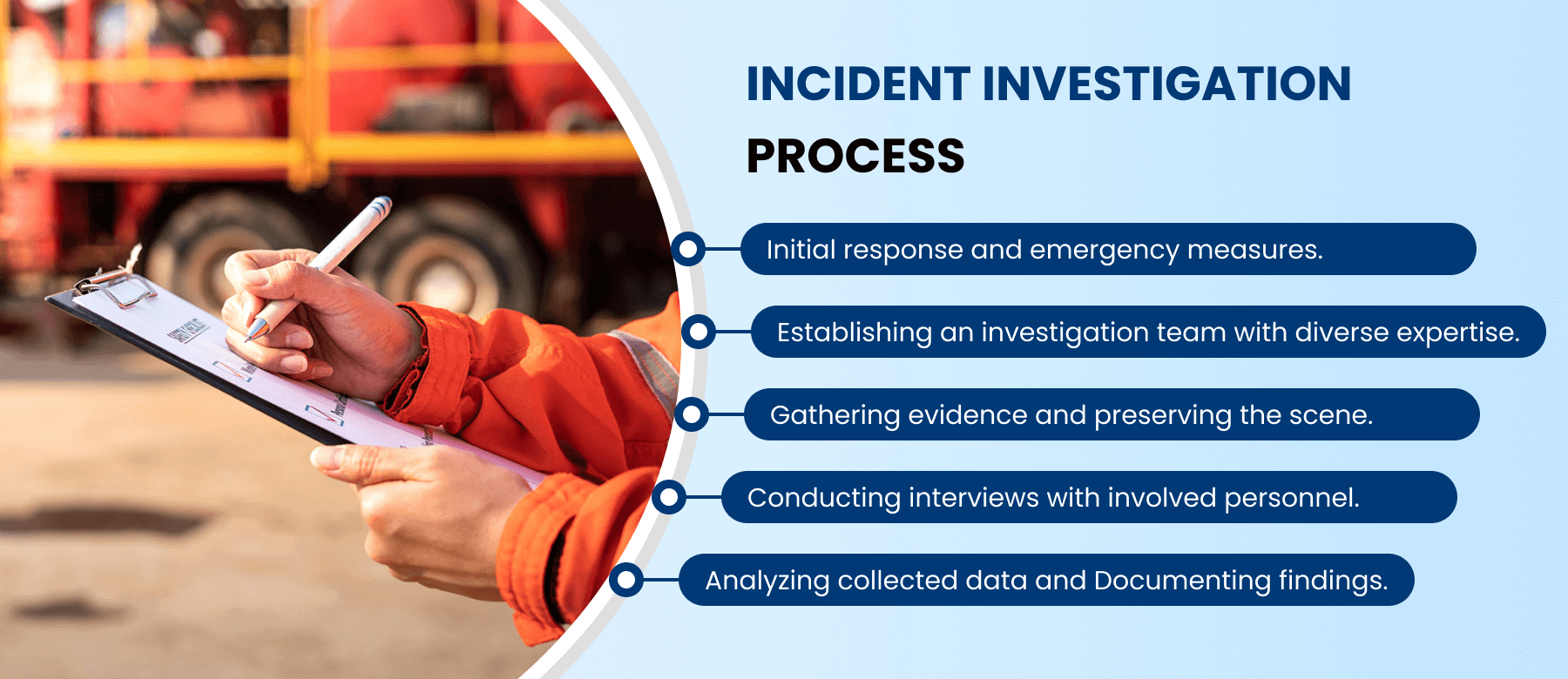

Incident Investigation Process

The PSM incident investigation process involves an initial response to ensure immediate safety and emergency measures. A diverse investigation team is established to gather evidence, interview involved personnel, and analyze collected data. The findings of the safety accident investigation are documented in a comprehensive report to identify root causes, implement corrective actions, and prevent future incidents.

Let’s look at each of these process steps.

Initial response and emergency measures

When an incident occurs, the priority is to ensure the safety and well-being of the individuals involved. This involves taking prompt actions such as providing first aid, evacuating the area if necessary, and implementing emergency response protocols to contain potential hazards.

Establishing an investigation team with diverse expertise

Once the immediate response is underway, forming a dedicated investigation team with diverse expertise is crucial for an effective PSM incident investigation. This team typically includes representatives from different departments or disciplines, such as safety professionals, engineers, operations personnel, and management. Their collective knowledge and perspectives will aid in conducting a comprehensive investigation.

Gathering Evidence and Preserving the Scene

To uncover the causes of an incident, it is vital to gather relevant evidence and preserve the scene. This may involve taking photographs, collecting physical samples, and securing any equipment or materials contributing to the incident. Preserving the scene in its original state helps ensure accurate analysis of process safety incidents accurately.

Conducting interviews with involved personnel

Interviews are crucial in understanding the events leading up to an incident. The investigation team will interview individuals involved in the incident, including witnesses and personnel directly affected. The team can uncover valuable insights into the factors contributing to the incident by gathering firsthand accounts and perspectives. Witness accounts are vital for uncovering key insights into the analysis of safety incidents.

Analyzing collected data and documenting findings

Once all relevant evidence and information have been gathered, the investigation team analyzes the collected data. This analysis involves reviewing incident reports, examining witness statements, studying relevant documents, and applying process safety incident investigation techniques to determine the root cause. The findings are then documented in a comprehensive report, which serves as a reference for implementing corrective actions and preventing future incidents.

Importance of Timely Safety Investigation

The significance of prompt incident reporting:

Timely incident reporting is crucial, allowing immediate attention to the incident analysis process. Reporting incidents promptly ensures that the appropriate response and investigation processes can be initiated promptly, reducing the risk of further harm and enabling a thorough examination of the event. Timely reporting allows immediate action, reduces risks, and enables thorough safety accident investigation.

Immediate actions to mitigate potential hazards

Timely safety investigations enable the identification of potential hazards and the implementation of immediate actions to mitigate them. By swiftly addressing and mitigating hazards, organizations can prevent further incidents or minimize their impact, protecting personnel, assets, and the environment. Timely reporting allows immediate action, reduces risks, and enables thorough safety accident investigation.

Preventing recurrence by identifying corrective measures promptly

Prompt investigations help identify the root causes of incidents, allowing for the timely implementation of corrective measures. By identifying and addressing the underlying causes promptly, organizations can prevent similar incidents from occurring in the future, enhancing overall safety and reducing the likelihood of recurring incidents.

Root Cause Analysis Techniques

The 5 Whys

The 5 Whys is a straightforward yet powerful technique that involves repeatedly asking “why” to identify the root cause of a problem. Delving deeper into each answer it helps uncover the underlying causes behind an incident and addresses them systematically.

Fishbone Diagram

The Fishbone Diagram, also known as the Ishikawa Diagram, visually maps out causal relationships between various factors contributing to an incident. It organizes potential causes into equipment, process, people, environment, and management categories, providing a comprehensive view and facilitating a structured analysis. It categorizes contributing factors for process safety incident investigation.

Fault Tree Analysis

Fault Tree Analysis (FTA) is a systematic approach to analyzing system failures and their interdependencies. It uses a graphical representation of events and their logical relationships, starting from the top event and working backward to identify the combination of failures that led to the incident. FTA helps uncover critical failure pathways and assists in implementing preventive measures.

Failure Modes and Effects Analysis (FMEA)

Failure Modes and Effects Analysis (FMEA) systematically identifies failure modes within a system or process. It assesses the impact of failures within PSM incident investigations. It involves analyzing each component or step, determining how it can fail, and evaluating the impact of each failure on the overall system. By identifying potential failure modes and their effects, FMEA enables organizations to prioritize preventive actions, enhance reliability, and mitigate risks before incidents occur.

Note: Each technique mentioned here is much more in-depth and complex. The descriptions provided are brief overviews.

Human Factors in Incident Investigation

Human error is a significant factor in process safety incidents, and understanding its role is crucial for effective incident investigation. Recognizing that humans make mistakes helps identify underlying factors such as fatigue, stress, inadequate training, or distractions that can lead to errors.

Human Reliability Analysis (HRA) is a systematic approach to evaluate the likelihood of human error in specific tasks or processes. Implementing HRA techniques, such as task analysis and error identification, helps identify potential human error sources, assess their probability, and suggest mitigation measures to reduce the risk of error.

Human performance is influenced by various organizational factors such as leadership, communication, procedures, and organizational culture. Investigating incidents should include assessing these factors to identify systemic issues that may have contributed to the incident. By addressing organizational factors, organizations can create an environment that supports human performance and reduces the likelihood of errors and incidents.

Documentation and Reporting

Comprehensive incident reports provide structured details for safety accident investigations, including the sequence of events, contributing factors, and identified root causes. They serve as a valuable reference for understanding the incident, implementing corrective actions, and preventing future occurrences. Additionally, comprehensive reports support regulatory compliance and facilitate learning from incidents.

Standardized formats ensure consistency in process safety incident investigation. By using predefined formats, organizations can capture essential information consistently, making it easier to analyze and compare incidents over time. Standardization also promotes effective communication and knowledge sharing among stakeholders.

Effective communication of investigation findings is crucial to ensure that relevant stakeholders are informed and can take appropriate actions. Sharing investigation findings with management, employees, and regulatory authorities promotes transparency, supports decision-making, and encourages a collaborative approach to prevent future incidents. Timely and clear communication fosters a learning culture and facilitates the implementation of corrective measures.

Learning from Incidents

Promoting a learning culture helps prevent process safety incidents. It creates an environment where incidents are viewed as opportunities for improvement rather than sources of blame. Encouraging open communication, fostering a non-punitive approach, and recognizing the value of lessons learned helps organizations continuously improve their processes, systems, and practices.

Sharing investigation findings within the organization is essential for spreading knowledge and raising awareness. Organizations can prevent similar incidents from occurring in different areas or departments by disseminating the lessons learned from incidents. Information sharing enables employees to understand potential risks, improve their work practices, and contribute to a safer working environment.

Tracking corrective actions ensures long-term improvements in PSM incident investigation. Identifying and implementing corrective actions based on investigation findings is crucial for preventing recurrence. Organizations should prioritize implementing preventive measures to address the root causes identified during the investigation. Furthermore, tracking the effectiveness of these corrective actions ensures that they are implemented successfully and remain in place to prevent future incidents. Regular evaluation and monitoring of the effectiveness of corrective actions enable organizations to improve their safety performance continuously.

Technology in Incident Investigation

Use of digital tools for data collection and analysis

Mobile apps, sensors, and wearable devices facilitate efficient data collection during incident investigations. These tools enable real-time data capture, reducing manual efforts and improving accuracy. Additionally, digital platforms provide capabilities for data analysis, allowing investigators to analyze large datasets quickly and uncover valuable insights.

Incident management software for streamlined investigations

Incident management software offers a centralized platform for managing the entire incident investigation process. It helps streamline data collection, evidence management, documentation, and collaboration among the investigation team. By automating workflows and providing a structured framework, incident management software enhances investigation efficiency, consistency, and accountability.

Leveraging data analytics to identify patterns and trends

Data analytics identifies patterns in the analysis of safety incidents. It uses advanced algorithms and machine learning techniques to identify patterns, trends, and correlations in incident data. Analyzing historical incident data helps uncover underlying causes and identify systemic issues. Organizations can proactively address potential risks, prioritize preventive measures, and improve overall safety performance by leveraging data analytics.

Conclusion

Process safety incident investigation is crucial in ensuring a safer workplace environment. By recapping the importance of these practices, we have seen how they help identify root causes, mitigate risks, prevent process safety incidents, and enhance workplace safety.

A strong PSM incident investigation framework ensures that incidents are not merely recorded but also analyzed for actionable improvements. However, it is not enough to simply react to incidents as they occur. Proactive measures must be taken to prevent incidents from happening in the first place. This requires a comprehensive approach that includes timely investigations, implementing corrective actions, and tracking their effectiveness.

Organizations must foster a learning culture where incidents are viewed as opportunities for improvement. Organizations can continuously enhance their safety performance by sharing investigation findings, prioritizing knowledge transfer, and implementing lessons learned. Let us prioritize process safety incident investigation, take proactive steps and learn from incidents to create a workplace where safety thrives.