Hazop Study & Gap Analysis

Process Risk Studies (PHA, HAZOP, PSSR, QRA, LOPA, RBI, SIL, FMEA)

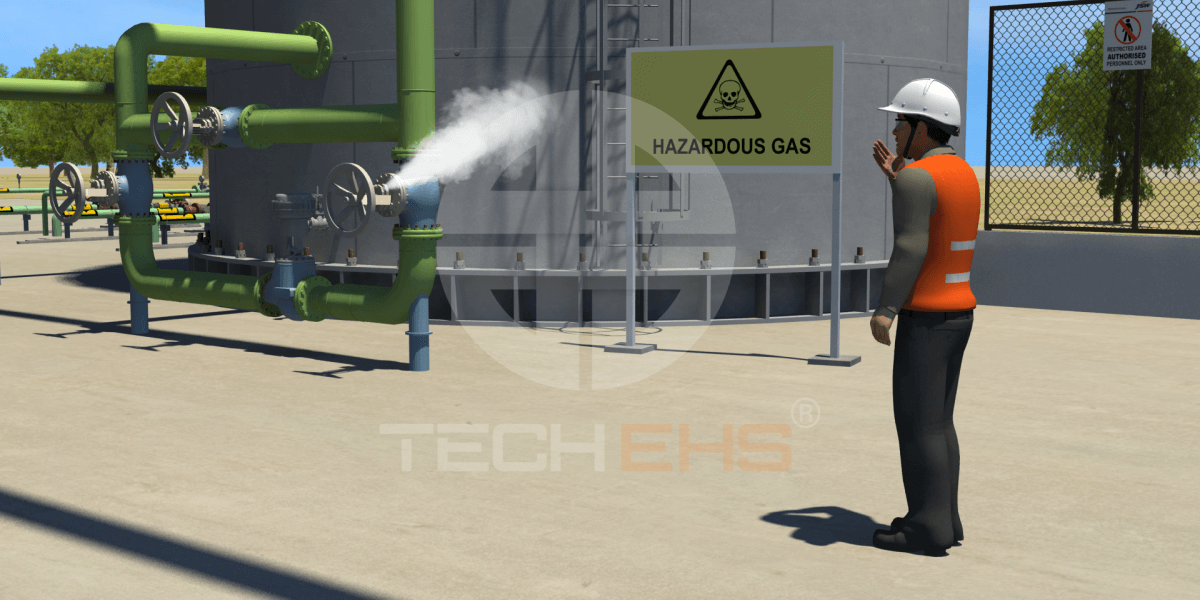

With a strong foothold in serving diverse industry verticals such as Construction, Manufacturing, Mining, Power, Oil and Gas, Petrochemicals, and Chemical sectors, TECHEHS stands as India’s premier integrated EHS&SG solutions provider. Our expertise extends from regulatory compliance to industry requirements, particularly in the realm of Process Hazard Analysis (PHA), encompassing methodologies like HAZOPS, QRA,PSSR,LOPA, SIL, RBI, among others.

Backed by decades of experience and collaborations with over 300 corporations and institutions worldwide, TECHEHS has emerged as the go-to partner for Public and Private enterprises seeking comprehensive PHA solutions. Our extensive experience spans across various industries, including EPC, Heavy Engineering & Infrastructure, Chemicals, Oil & Gas, Power & Energy, Metals & Alloys, Pharmaceuticals, Automotive, and public utilities, including atomic power.

This rich and diverse experience has not only honed our skills and processes but has also propelled us to a leadership position in the EHS & SG industry today. TECH EHS is recognized as a pioneer in domain excellence, offering unparalleled expertise and support to organizations aiming to achieve excellence in process risk management and safety.

Process Risk Studies

There are several different types of Process Safety Studies that can be conducted. The most common types that we undertake are:

PHA – Process Hazard Analysis PHA, or Process Hazard Analysis, is a systematic method used to identify and evaluate potential hazards associated with chemical processes. It involves examining the design, operation, and maintenance of a process to identify any conditions or scenarios that could lead to accidents or harm to personnel, the environment, or assets. PHA aims to proactively mitigate risks and enhance safety by implementing appropriate control measures and safeguards.

Key Features

HAZOPS – Hazard Operability study HAZOP is a systematic method used to identify potential hazards and operability issues in chemical process systems. It involves a multidisciplinary team scrutinizing each element of a system to uncover deviations from the intended design conditions that could lead to hazards or operational problems. Through a series of guided brainstorming sessions, HAZOP aims to enhance safety, reliability, and efficiency in process operations.

Key Features

QRA – Quantitative Risk Assessment QRA is a comprehensive analysis methodology used to quantify and evaluate risks associated with industrial processes, including chemical plants, oil refineries, and other high-risk facilities. It involves the systematic evaluation of potential hazards, their frequencies, consequences, and associated risks. QRA integrates probabilistic methods to provide numerical estimations of risk levels, aiding in decision-making for risk management and mitigation strategies.

Key Features

PSSR- Pre-Startup Safety Review is a structured process conducted before commissioning or restarting a process facility to ensure that all safety-critical systems, procedures, and controls are in place and functioning correctly. It involves verifying that the process equipment, instrumentation, and operating procedures meet design specifications and regulatory requirements to prevent incidents during startup activities.

Key Features

Inspiring Stories

Testimonials from Industry Pioneers

One of the advantages of awarding the contract to TECH EHS is that they have expertise in the field and they are easily able to understand our requirements with very minimal consultation. It would be easy for us to roll out the projects within the stipulated time. We have partnered with TECH EHS for many animation projects, software project and continue to use their services to this day. The net result of our association has been very fruitful and productive. Keep it up TECH EHS!

TECH EHS has provided Employee ID Badging Software & Onsite Manpower solutions to IOCL. We state that your Team is providing the best services to our Corporation. We have no complains till date and are satisfied.

We wish TECH EHS Good Luck….! Keep it up….!

We needed a customized solution, as the sheer scale of our operations demanded accurate estimates of scaffolding equipment and manpower. Older methods resulted in significant time delays to scaffolding operations. Through our close discussions, TECH EHS proposed a workflow for SMS that fitted the bill, perfectly. Ultimately, this led to an overall reduction in delays and a streamlined scaffolding lifecycle.

We were looking for a competent solution for our scaffolding operations spanning multiple sites. Scaffolding management system offered us the ability to shift from a basic to digitalised all-in-one platform.This has enabled efficient scaffolding operations providing inspected and safer material, effortlessly. What helps our case even more is the software availability in local language (Chinese) and English.

TECH EHS developed TATA Projects Safety Induction DVD with 3D animation & audio. This induction video explains various construction activities & the safety measures required to mitigate the risks involved. This animation movie has been the result of careful deliberation and effort put in by both TECH EHS & TPL’s corporate EHS & construction services teams to illustrate various safety aspects in construction activities in an easily understandable manner.

TECH EHS’ services have been beneficial and helped to lift the standard of Safety within our organization, by making personnel aware at various establishments in different countries, about the near misses or accidents scenario, using the medium of Animation videos.

The work done by TECH EHS to understand, plan and execute the final video is highly appreciable and executed fast. The outcome of this is that the animation video can even be understood by laymen. This will go a long way to make many people understand safety in simple way and prevent incidents and hence well-being of one and all

For the service part, we appreciate your work, also you have created a virtual world for learning, training and communicating safety in form of animation movie

Our Clients