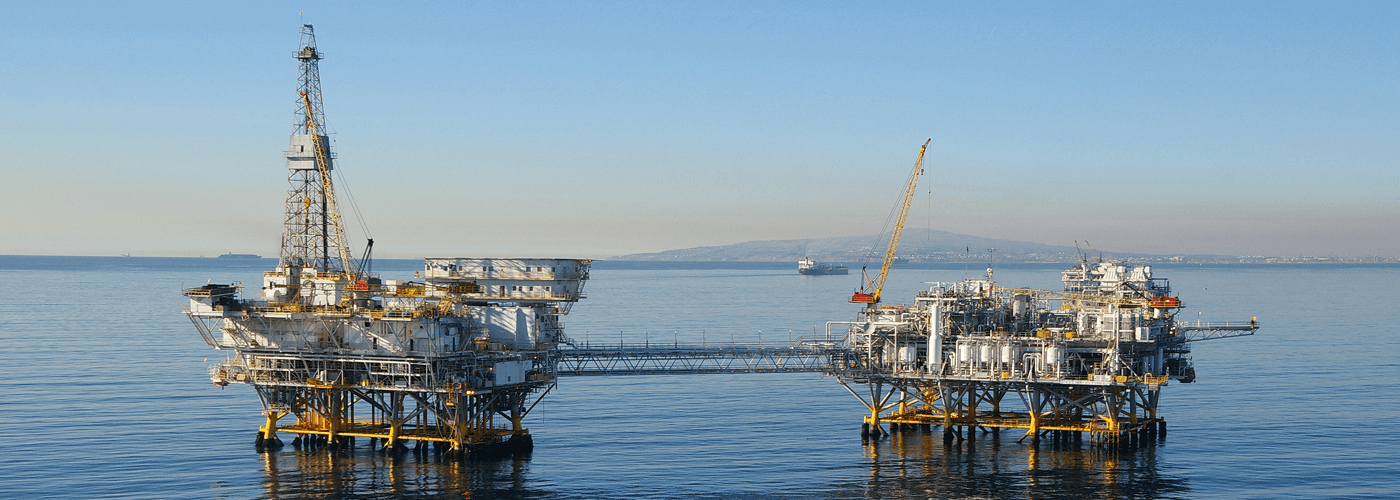

Innovative technological solutions driving efficiency, safety, and sustainability in oil & gas.

Operating in one of the world’s most hazardous and heavily regulated industries, oil and gas companies face daily challenges—ranging from high-risk field operations and environmental compliance to managing remote crews and contractor safety. Traditional safety processes often fall short, leading to reporting delays, missed hazards, and inconsistent training oversight.

Overcoming Oil & Gas Industry Challenges with Smart EHS Management

We built our EHS management software to meet these complex demands head-on. With real-time visibility, automated compliance tracking, and mobile access for field teams, our solution empowers oil and gas operators to streamline safety processes, reduce risk, and stay ahead of regulatory requirements.

From incident reporting to workforce training and environmental monitoring, we help you create a safer, smarter, and more compliant operation—no matter where your crews are work.

Manual PTW systems in oil and gas operations pose significant operational risks. These include unauthorized simultaneous operations (SIMOPS), incomplete energy isolation during maintenance, and poor team coordination. Manual tracking can lead to overlapping permits, missed handovers, and human errors, increasing the likelihood of equipment damage, safety incidents, and costly production shutdowns. Additionally, the lack of automation and integration with control systems heightens the risk of delayed responses and regulatory non-compliance.

Avoid PTW Failures with a Smarter, Digital Approach

Failures in the PTW system can lead to serious safety risks, operational delays, and compliance issues. Common causes include incomplete permit details, bypassed procedures, miscommunication between teams, and poor tracking of active or past permits. Our digital PTW solution eliminates these risks with real-time visibility, automated workflows, and accurate record-keeping—ensuring every permit is transparent, compliant, and controlled.

Oil and gas industry operations are done in high-risk environments. Near misses and accidents often go underreported or poorly communicated, leading to repeated mistakes and preventable incidents. Traditional incident reports can be difficult to interpret and fail to resonate with frontline workers. Making incident data understandable and actionable is crucial to diminishing the recurrence of unsafe events.

Turn Lessons Learned Into Life-Saving Awareness

Our solution brings these scenarios to life through 3D recreations, turning complex incidents into clear, visual stories that engage all workforce levels. This powerful communication tool enhances awareness and drives a deeper understanding of risks, encouraging proactive behavior and a stronger safety culture across your organization

We’ve developed 3D recreations for a wide range of incidents, including: IFO Leak Incident, HGU Exchanger Rupture, Fatal Incident at WWTP, Flash Over at SS#2, Fire at CCR and CDU II, HCU AFC Leakage & Fire Case Study, Product Transfer Incident, Fire at DHDS ETP OWS Sumps, NV3 Incident, CCR Unit Burn Injury, Hot Oil Blow Down Line Incident, Bitumen VG 30 Leak, Emergency Diesel Generator (EDG) Incident, Fire in Vessel (V-70), Dropped Object Through Hole, Hydro Test Activity Incident, Bhopal Gas Tragedy Recreation, Worker Falling into Open Tank on Oil Rig, Crane-Mast Incident, Fire at Injection Compressor, Employee Crushed Between Catwalk Edges.

Onboard and Upskill Contractual Workers—Faster and Smarter

Speed up onboarding and training for contractual workers without compromising quality. Whether it’s safety induction for refineries, offshore platforms, or onshore facilities, animated training ensures consistent, engaging, and standardized learning for every worker—saving time and reducing reliance on repetitive live sessions.

More than just training, animation helps reinforce your brand identity—making a strong first impression while communicating your company’s culture, values, and safety expectations from day one.

“ One of the driving factors in our decision to choose you was the quality of the video animation work you had previously done with one of our JV partners. Your knowledge of EHS is commendable. ”

JIGPC (Jazan Integrated Gasification and Power Company), Saudi Arabia

Simplify Complex Procedures with 3D Animated SOPs

Boost understanding of critical equipment and high-risk processes with 3D animated Standard Operating Procedures (SOPs). Traditional text-heavy manuals often fail to convey the whole picture—especially for intricate technical operations. Our animated SOPs visually break down complex steps, making procedures easier for operators, engineers, and trainees to grasp, retain, and follow..

We’ve developed 3D SOPs on a wide range of topics for various clients, including gasification, CO₂ capture, catalytic cracking, oil transfer to vessels, LNG loading, bitumen handling, LPG filling, extruder and compressor systems, hot oil commissioning, flare light-up, and many more. With step-by-step visual guidance, teams gain clearer insights into how to perform critical operations safely and effectively—reducing errors, downtime, and safety risks.

Deliver Engaging, High-Impact Hazard Awareness Training

Safety training must go beyond checklists and manuals in an industry with high stakes. Animated training content brings hazard awareness to life—making critical procedures easier to understand, remember, and apply in real-world scenarios.

From H₂S awareness and detector usage to respiratory equipment procedures, emergency response, and defensive driving, our tailored animations provide clear, visual guidance that reinforces best practices and strengthens your safety culture. Whether for technical training or operational walkthroughs, this approach helps reduce risk, improve retention, and prepare your workforce for high-risk environments.

“ The team’s deep understanding of HSE activities ensures a smooth transition. They quickly grasp our expectations and industry-specific requirements, making the process efficient and well-structured.”

Sylvain Duperrier, Technical Advisor

Rubis Energy, France

Improve access time during maintenance & shutdowns

Manual scaffolding operations lead to inefficiencies, delays, and safety risks. Tracking requests, materials, and locations is slow and error-prone without digital tools, causing resource mismanagement and project delays. Inconsistent inspections and lack of real-time updates compromise safety and compliance. Additionally, manual documentation makes it difficult to maintain accurate records and can result in billing inaccuracies and inflated project costs.

Overcome Scaffolding Challenges with Streamlined Solutions

Optimize scaffolding operations during maintenance and shutdowns with Scaffold Operations Management Software, offering seamless coordination and real-time data.