Smarter EHS for the Chemical Industry – Streamline Compliance, Strengthen Safety

Chemical manufacturing presents unique safety and compliance challenges, from managing hazardous reactions and volatile compounds to ensuring seamless coordination between operations, maintenance, and contractors. Manual systems often fail to maintain consistency, visibility, and accountability across sites.

We have designed our EHS Management Software to meet these challenges head-on. It digitizes your critical safety processes, enables smarter decisions, and reinforces a proactive safety culture across the organization.

With real-time dashboards, mobile-enabled reporting, and visual training support, our platform empowers teams to operate safely, efficiently, and in full regulatory compliance.

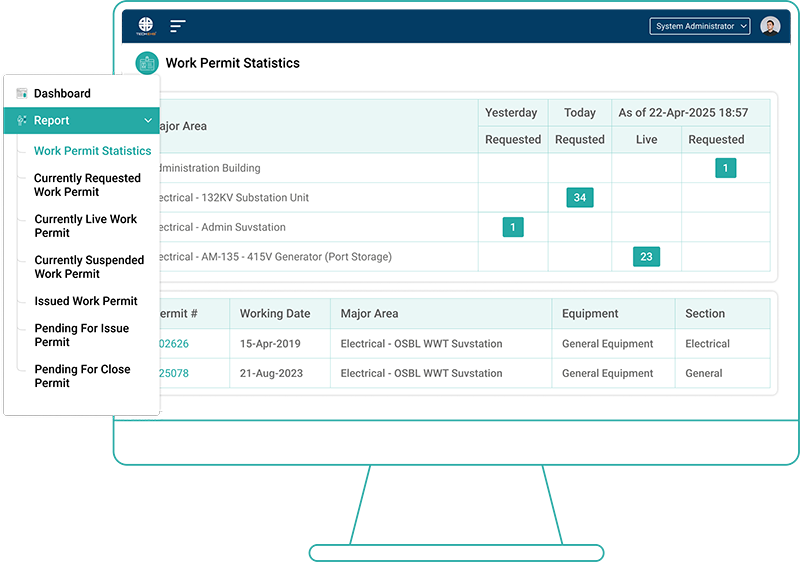

Eliminate Permit-to-Work Failures in Chemical Plants with a Smarter, Safer Digital Approach

Manual Permit-to-Work (PTW) systems are increasingly proving to be a liability in complex and high-risk environments like chemical plants.. Relying on paper-based or semi-digital processes often leads to:

These inefficiencies can result in equipment damage, production downtime, safety incidents, and regulatory penalties—all of which impact operational continuity and corporate reputation.

“ TECH EHS Team is knowledgeable in solving and giving suggestions to the E-PTW and WMS system that we worked with. We appreciate and value your support and service. ”

Kraiburg PTE Singapore

Amelia Ng Pui Yee, Senior EHS Executive

Inform, Align, and Empower: 3D Animated Safety & Technical Training for the Chemical Industry

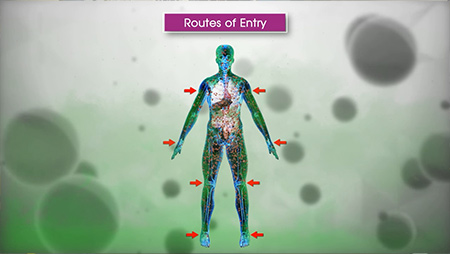

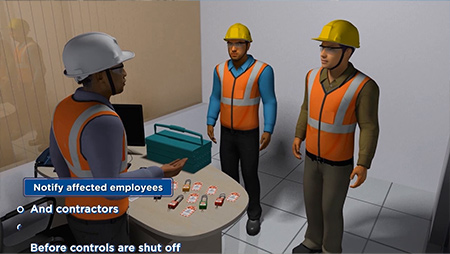

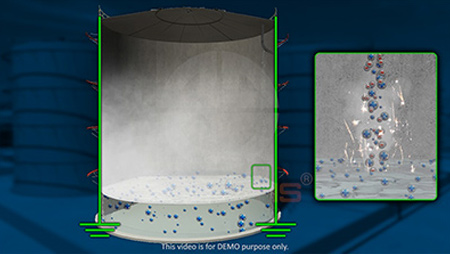

In the high-stakes world of chemical manufacturing, safety is not just compliance—it’s culture, clarity, and constant vigilance. With the presence of flammable, toxic, reactive, and potentially life-threatening substances, it is critical to ensure that every worker, visitor, and contractor understands operational protocols.

To address the complexity and hazards of chemical operations, we have developed a comprehensive suite of 3D animated safety, SOP, and technical training modules explicitly crafted for the chemical industry. These immersive, realistic training tools turn critical knowledge into visual experiences—making complex procedures easier to understand, retain, and follow.

We have developed animated training content to reflect real-world scenarios and challenges in chemical operations, helping our clients stay safe, informed, and prepared from day one.

“ We have partnered with TECH EHS for many animation projects, software projects and continue to use their services to this day. The net result of our association has been very fruitful and productive.”

USV Limited, India

Suresh Penmatsa, Assistant Vice President, EHS