Tackling EHS Challenges in the Metal & Mining Industry with Smart Digital Solutions

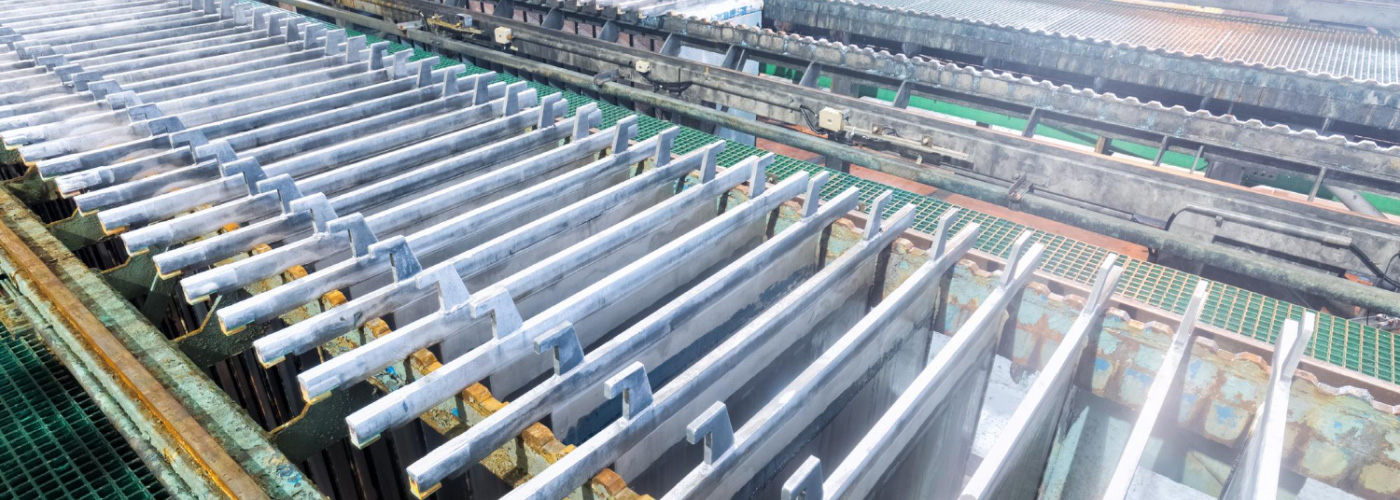

In one of the world’s most hazardous and tightly regulated environments, metal and mining companies face daily safety and compliance challenges—from managing high-risk operations and heavy equipment to controlling exposure to toxic substances and extreme temperatures. Inconsistent reporting, delayed response to hazards, and fragmented training often limit the effectiveness of traditional EHS systems.

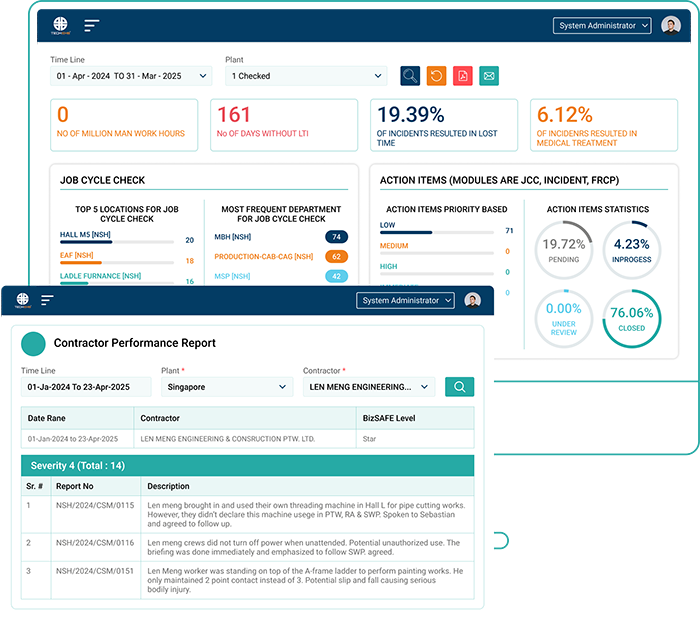

Our EHS management platform is purpose-built to address these complexities head-on. With real-time visibility, automated compliance tracking, and mobile-first tools for on-ground teams, we help streamline your safety workflows and drive accountability from pit to plant. Whether managing incidents, monitoring equipment, or ensuring contractor safety, our platform enables teams to stay compliant, reduce downtime, and foster a proactive safety culture.

Modules Designed for High-Risk Mining & Metal Operations:

“ TECH EHS has been a great partner in accelerating and elevating our EHS journey. With “a click of a finger,” the platform could retrieve and present any useful information or data.”

Natsteel Holdings, Singapore

Smarter PTW for Smelters, Refineries, and Mining Operations

In high-risk environments like smelters, refineries, and mines, manual Permit to Work (PTW) processes leave too much room for error. These gaps can escalate into serious incidents, from inadequate isolation during maintenance to unauthorized entries in confined spaces and uncoordinated SIMOPS.

Our Digital PTW Solution brings structure, visibility, and control to the entire permit lifecycle, minimizing risk and ensuring safe execution of every task.

Key Features:

Empower teams with the tools they need to execute jobs safely, efficiently, and with full compliance—every time.

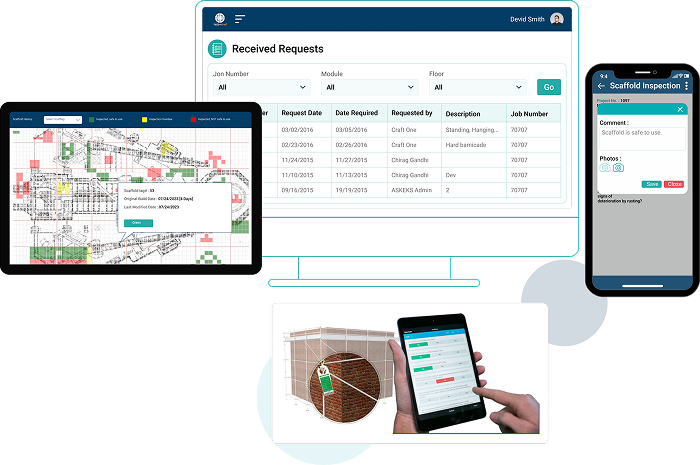

Optimize Scaffold Safety in Shutdowns & Maintenance

Scaffolding Management for Complex Industrial Yards

Manual scaffolding processes in coke ovens, acid plants, and casting areas often lead to inefficient coordination, delayed inspections, and safety gaps.

Our Scaffolding Management Software streamlines:

With efficient scaffolding operations, you can reduce downtime, improve safety compliance, and gain complete control over your maintenance and shutdowns.

Simplify Complex Procedures with 3D Animated SOPs

Traditional text-based SOPs often fail to explain high-risk, technical procedures, especially in complex environments like smelting units, casting plants, and refineries. Our 3D animated SOPs transform these static documents into clear, visual learning tools that enhance comprehension, retention, and safe execution.

These animations visually guide operators, engineers, and contractors through step-by-step procedures, covering equipment handling, critical safety checks, and process flows with unmatched clarity. They are especially impactful for multilingual, shift-based teams working in dynamic and hazardous environments.

We have developed SOPs for various clients in the Metal and mining industry, such as Battery Process Units, Coke Oven by-product and main Unit SOPs, Mantle and Bowl Liner Replacement, Cast House Operations, Claus Units for Sulphur Recovery, Scaling Operations, and Silver Refinery Process.

These animations reduce training time, improve retention, and standardize execution—especially useful for multilingual teams and shift-based operations.

3D Animated Incident Recreation – Learn from the Past, Protect the Future

Organizations overlook and misinterpret traditional incident reports—missing the opportunity to influence behavior. Our 3D animated incident recreations bring real-life safety events to life, turning them into powerful visual lessons that resonate across all levels of your workforce.

Safety teams use these animations in toolbox talks, safety briefings, contractor inductions, and leadership walk-throughs—ensuring that critical safety messages are heard, remembered, and applied.

We have recreated Incidents into 3D animated movies for various clients in the Metal and mining industry. Incidents include a Forklift Collision, a Slag Raking Machine Mishap, an SP II Fatality Case, a Flashover in MRSS, Roadway Accidents in a Scrap Yard, Boiler Bundle Replacement, a Coke Yard Fire, a Purification Hydro LTI Incident, Shell Debris and Loco Car Accidents, a Worker Injury in an Acid Plant, a JCB Loader Incident, an OWC Machine Malfunction, and a Hot Water Burn Incident.

Each animation helps teams visualize what went wrong, understand contributing factors, and adopt safer practices. These aren’t just recreations—they’re culture-shaping tools that prevent history from repeating itself.

“ For the service part, we appreciate your work, also you have created a virtual world for learning, training and communicating safety in form of animation movie”

BALCO

Gagandeep Ojha, Safety-in-Charge

3D Visualizations for Technical Process Proficiency

Equip your workforce to understand end-to-end operations with 3D technical process simulations—especially valuable for engineers, operators, and new recruits.

We have developed 3D technical movies for various clients in the Metal and mining industry such as Acid Plant Operations, Roaster, Leaching & Purification, Cell House Workflows, RMH, Refining, Melting & Casting, CPP-CHP & Switchyard Operations, Hot Metal Handling & SO₂ Risk Zones, Lead CO Safety & Ventilation Requirements, LDO Yard Handling Protocols

Drive precision, reduce operational errors, and ensure safety through a crystal-clear understanding of complex process flows.

Safety Induction, Visitor Awareness & Plant Walkthroughs

First impressions matter. Use animated visitor walkthroughs and contractor inductions to deliver consistent, site-specific safety messaging.

Includes:

These are delivered via kiosks, mobile devices, reception, or control room displays—ensuring readiness before step one.

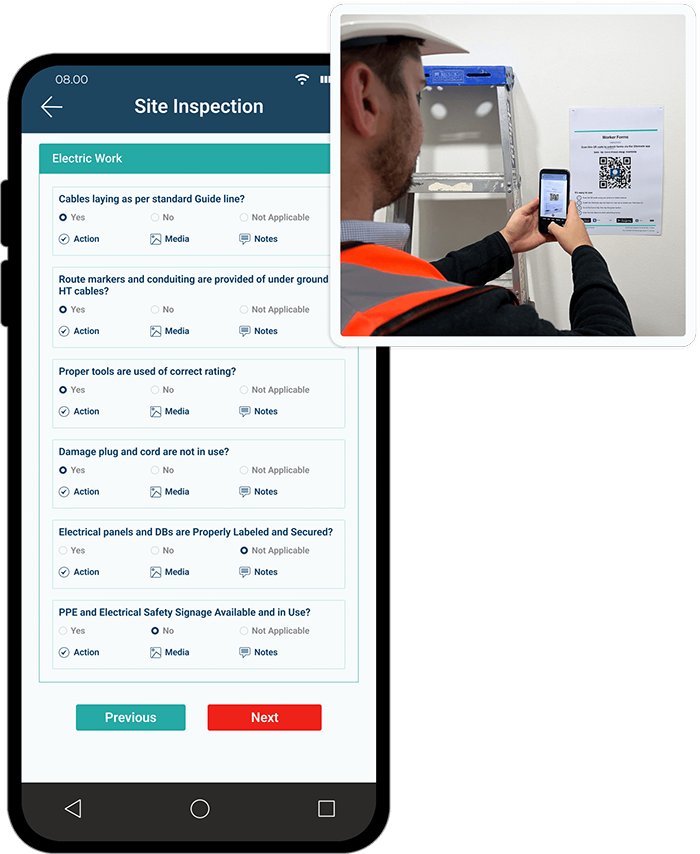

Mobile-First Safety with QR Code Observations

Your workforce is mobile—your safety system should be, too.

Organizations empower on-ground teams to scan QR codes and report real-time safety observations with few clicks using mobile devices.

Key Mobile Capabilities:

Enable safety on the move—anytime, anywhere.