Manufacturing environments are complex and high-risk by nature. Operators work around high-speed machinery, elevated structures, hazardous chemicals, and high-heat processes—all while meeting tight production deadlines. Managing safety in such dynamic conditions is a constant challenge.

Despite these risks, many manufacturing facilities still rely on paper-based systems or disconnected tools to manage their EHS functions. This results in delayed incident reporting, missed safety inspections, incomplete corrective actions, inconsistent workforce training, limited visibility across departments or sites, and increased exposure to compliance and regulatory risks.

These gaps affect safety outcomes and operational efficiency, team accountability, and audit readiness.

Transforming Manufacturing Safety with Smart EHS Software

We designed our EHS Management Software to address these challenges head-on by transforming traditional safety practices into a connected, digital-first ecosystem. It allows manufacturers to centralize, automate, and streamline all safety and compliance activities from a single platform.

By digitizing and integrating safety processes across facilities, you can:

With our solution in place, safety is no longer a box to check—it becomes a shared responsibility, embedded into daily operations and driven by data.

Transforming Manufacturing Safety with Smart EHS Software

“I recommend TechEHS software tools to everyone for effective implementation of EHS Management system. ”

V-Guard Industries Ltd.

Prakash V., DGM EHS

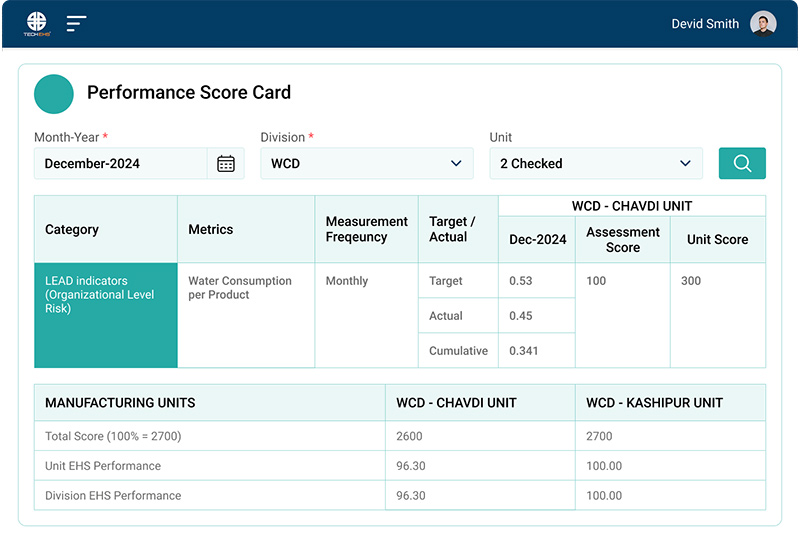

Manufacturing operations generate vast amounts of EHS data—from incident reports and safety inspections to training records and risk assessments. However, this data remains scattered across disconnected systems, spreadsheets, or departments. Safety teams struggle to identify trends, respond quickly to risks, or align decision-making across levels without centralized visibility. Such challenges lead to reactive safety practices, missed compliance requirements, and limited site-level or enterprise-wide performance insight.

The Solution: Business Intelligence for EHS in Manufacturing

Business Intelligence (BI) bridges the gap between raw data and actionable insights. Our BI-enabled EHS platform transforms fragmented safety data into real-time dashboards, reports, and trend analysis, empowering every level of the organization to act smarter and faster.

Whether you’re a site supervisor identifying hazard hotspots or a VP tracking compliance across multiple locations, BI turns safety into a shared, measurable business value.

Key Benefits of BI in EHS for Manufacturing

Business Intelligence improves EHS reporting and elevates your entire manufacturing safety strategy. Integrating BI into your EHS framework creates a proactive safety culture that drives performance, compliance, and accountability across the board.

Avoid Manual PTW Pitfalls with Digital Permit to Work

Manual Permit to Work (PTW) systems in manufacturing plants create risk exposure, particularly during maintenance shutdowns or equipment servicing. Common failures include unauthorized operations, inadequate isolation, missed handovers, and overlapping work, all of which can lead to injuries, equipment damage, or production delays.

Our digital PTW solution improves accuracy and control with real-time permit status tracking, multi-level approvals, electronic signatures, isolation tagging, and full audit trails. Teams gain visibility into active permits, ensuring no task begins without proper safety controls.

Simplify Complex SOPs with 3D Animated Guidance

Manufacturing processes often involve intricate machinery and critical steps that traditional text-heavy manuals fail to explain clearly.

Our 3D animated SOPs break down complex procedures—like extrusion, injection molding, CNC operations, furnace startup, or robotic arm programming—into easy-to-understand visuals. These animated movies ensure better comprehension, fewer errors, and safer execution by operators and technicians alike.

We’ve transformed critical SOPs into engaging visual formats, reducing training time and improving retention for our clients in manufacturing. Examples include:

“ In our long-term engagement in multiple projects, the TECH EHS team’s punctuality and reliability have been crucial in keeping our projects on track and ensuring timely delivery. ”

Siemens

“ TECH EHS’ services have been beneficial and helped to lift the standard of Safety within our organization, by making personnel aware at various establishments in different countries about the near misses or accidents using the medium of Animation.”

Phil Kinney, Corporate Safety Head

GKN

Bring Incident Lessons to Life with 3D Visualizations

Manufacturing organizations document incident investigations in complex reports that don’t always resonate with frontline workers. As a result, they hardly retain the critical lessons learned, leading to repeated errors and preventable events.

Our 3D animated recreations transform past incidents into clear, engaging stories that drive deeper awareness and understanding. This powerful approach boosts engagement, strengthens proactive safety behavior, and ensures key lessons are remembered and applied across the workforce. As an organization, you can incorporate these quickly developed videos into your existing training or eLearning or share them across plants at strategic locations such as entrances, cafeterias, or similar areas to raise mass awareness.

Mold Incident, Blade Drilling Dual Laceration, Finger Cut During Bag Change, Slip & Trip on Ramp, On Pallet Loader Incident, and Slipped in Machine Incident. These visualizations have helped companies to drive deeper hazard awareness and reduce repeat occurrences.

Deliver High-Impact 3D Animated Training & Awareness

In manufacturing, where workers face physical, chemical, and ergonomic risks every day, safety training needs to be more than just informative—it needs to be memorable, engaging, and practical.

Our 3D animated training modules bring real-world scenarios to life, helping teams understand risks, follow procedures, and build a proactive safety mindset. From hazard-specific learning to environment-conscious awareness, our content empowers every level of the workforce.

eLearning for Manufacturing Teams

Equip your workforce with on-demand, role-based training tailored to high-risk and dynamic manufacturing. Whether machine safety, SOP adherence, hazard awareness, or emergency response, our 3D animated and interactive eLearning modules simplify complex topics through engaging visuals and real-world scenarios.

We have designed each training module for assembly line operators, maintenance crews, supervisors, and contractors to reflect the day-to-day challenges faced on the shop floor. This ensures your teams are confident, compliant, and safety-ready from day one.

Modules We’ve Delivered for Leading Manufacturers:

Improve access time during maintenance & shutdowns.

Manual documentation in scaffolding operations leads to inefficiencies, delays, and safety risks. Tracking requests, materials, and locations is slow and error-prone without digital tools, causing resource mismanagement and project delays. Inconsistent inspections and lack of real-time updates compromise safety and compliance. Additionally, manual documentation makes it difficult to maintain accurate records and can result in billing inaccuracies and inflated project costs.

Overcome Scaffolding Challenges with Streamlined Solutions

Optimize scaffolding operations during maintenance and shutdowns with Scaffold Operations Management Software, offering seamless coordination and real-time data.