Client Industry

Manufacturing Facilities and Technology Centers

Organization Size

25000+

Solution

Animated Recreation of Accident and Incident Scenarios

Challenge

Traditional Methods Used for Awareness

Ineffective Understanding of Accident/Incident

The primary objective of sharing the short movies within the client’s network was to avoid reoccurrence and spread awareness.

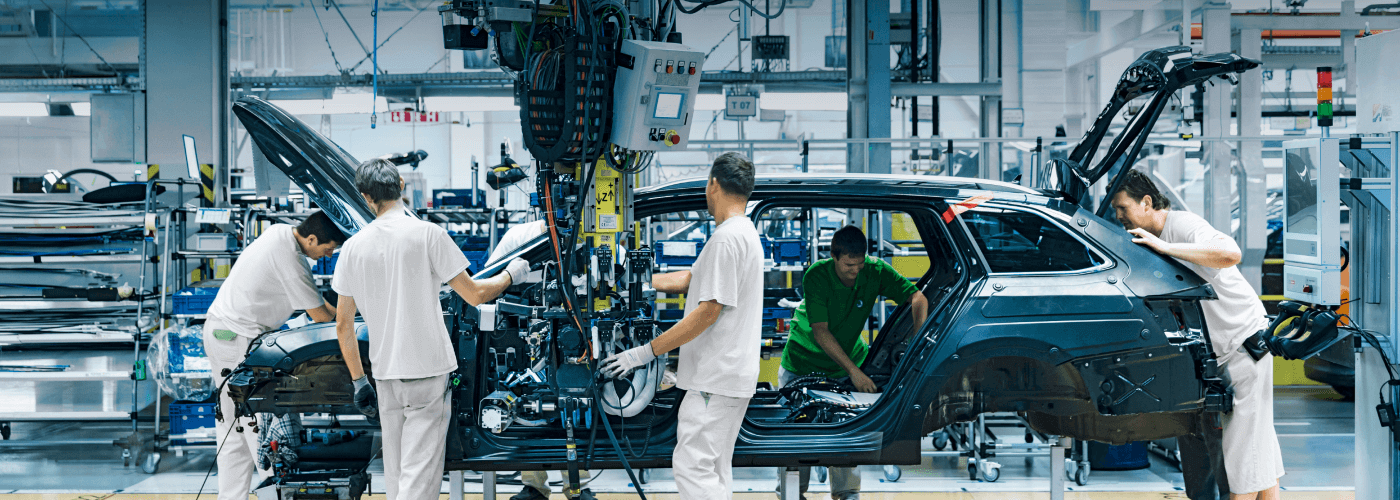

Our client, GKN Automotive, employs around 25,000 people across 47 manufacturing facilities and six technology centers in 19 countries. They wanted a sharing mechanism that would allow them to share accident/incident/near-miss information globally from any of their plants speedily and effectively.

However, their existing process was primarily text-based communication via emails. A report was prepared after the accident/incident happened and shared across their plant network.

The report’s preparation was limited, and critical precaution points were not captured. This, in turn, resulted in little or no understanding of the accident/incident once it was shared.

Solution

Exact sequence of events explained

Precise knowledge of accident/incident

Clear understanding of what went wrong and why

We did a thorough evaluation process using actual images of the plant/equipment/machinery, and a brief was given by the organization undertaken to uncover the thread of events. Then, a storyboard was prepared using an exact sequence of events as explained.

Precise 3D models of actual elements from the scenario were used to create the animated video, which was completed and delivered in digital format within a short period of time.

The client then shared the video link across its plant network, significantly reducing time and costs. Since the video accurately depicted actual events, minimal explanation or theoretical context was needed.

These videos were displayed in key strategic areas such as cafeterias and high-traffic workforce locations, ensuring rapid awareness of critical incidents and near misses across multiple global plants.

With no voiceover, language barriers were eliminated. The short videos are practical tools for quick awareness during training sessions, toolbox talks, and refresher courses.

Thus, this approach has proven to be a fast, cost-effective, and impactful way to enhance safety awareness and compliance across global operations.

Outcome

Greater awareness among workmen, yielding significant ROI.

Faster sharing of scenarios within the internal network.

Drastic decrease in accidents and incidents.

Benefits

Time Savings

Reduction in Accidents/Incidents

Significant ROI

Increased Awareness

Interested in a similar solution?

Reach out to us to discuss your needs and discover how we can create a customized solution that perfectly aligns with your goals. Let’s innovate together!