Managing employee health and safety across multiple job sites, diverse contractors, and high-risk activities is a cumbersome challenge in the construction industry.. Projects often face tight deadlines, evolving site conditions, and a diverse workforce, making it difficult to maintain consistent safety practices. Traditional manual processes can lead to delayed incident reporting, overlooked hazards, poor communication, and compliance gaps—ultimately exposing workers to risk and pushing companies to legal and financial penalties.

Tackling Construction Safety Challenges with Smart EHS Management

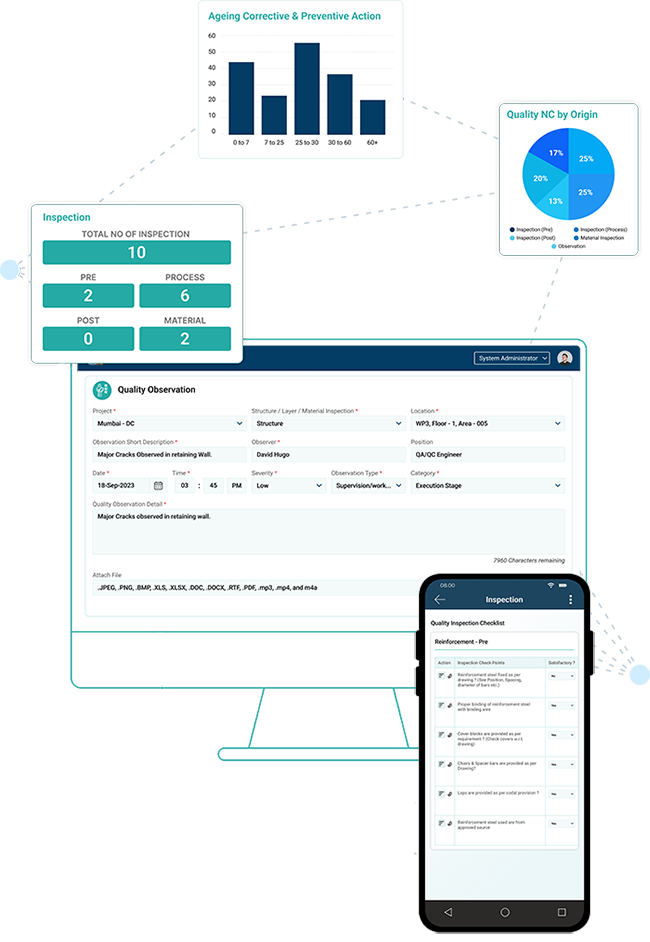

Our EHS management software is built to take these challenges head-on. Mobile and web-based access enables seamless reporting of incidents, near misses, hazards, and field observations in real time. From initial reporting to investigation, assigning corrective actions, and tracking them through closure, our system ensures end-to-end accountability. Configurable checklists support site inspections, equipment assessments, and permit-to-work processes, while built-in scheduling tools help meet regulatory requirements.

By promoting collaboration among employees, contractors, and vendors, the platform fosters a proactive safety culture. It empowers teams to prevent incidents before they happen and elevates on-site safety performance across every phase of construction.

Manual Permit-to-work (PTW) systems in construction projects present serious safety and coordination challenges—mainly when multiple contractors and agencies operate simultaneously on complex sites. Paper-based permits often lack real-time visibility, accurate location data, or detailed activity descriptions, leading to unauthorized work, missed safety checks, and poor coordination. Delays in approval, overlapping tasks, and missed handovers can result in work disruptions, safety incidents, and schedule overruns. Without centralized control, managing high-risk activities becomes inefficient and error-prone, putting people and project timelines at risk.

Smarter Digital PTW: A Safer, Faster, and More Controlled Approach

Our digital Permit to Work solution is designed specifically for the complexity of construction environments—providing real-time visibility, streamlined workflows, and enhanced safety compliance. With mobile and web-based access, users can raise permits, review, and quickly approve them from the field, with precise location tagging, detailed job descriptions, and integrated safety checklists that must be verified by authorized personnel. The system ensures that every task is clearly defined, authorized, and scheduled—minimizing delays and reducing the risk of unsafe operations.

By digitizing the entire PTW lifecycle—from application and risk assessment to approval, monitoring, and closure—construction teams can better coordinate work across multiple agencies, manage SIMOPS risks, and ensure adherence to project deadlines. The result is a more proactive safety culture, improved accountability, and greater operational control across every job site level.

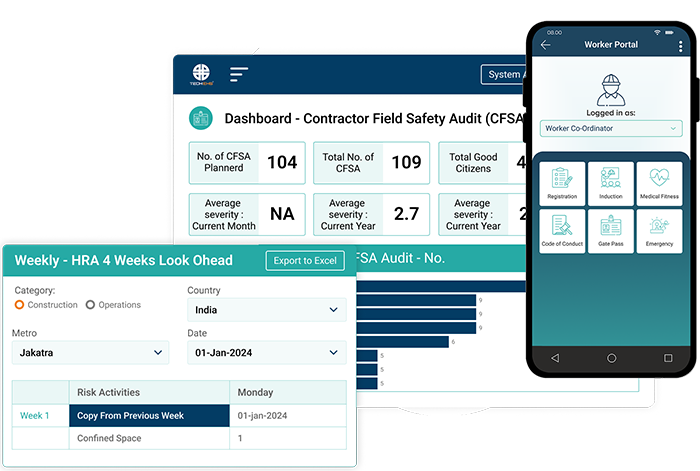

Digital Contractor Safety Management: From Onboarding to On-Site Excellence

Managing contractor safety across fast-moving construction sites can be complex, with multiple vendors, large number of workers, and equipment entering and exiting daily. Manual processes often lead to inconsistent onboarding, missed documentation, and weak compliance tracking. Our Contractor Safety Management solution digitizes and centralizes every step—from contractor onboarding, training, and certification tracking to performance monitoring and access control integration—ensuring that only trained and authorized personnel are allowed on-site.

Through a dedicated contractor and vendor portal accessible via web and mobile, organizations can easily manage worker profiles, vehicles, equipment, and compliance documents. The built-in training portal simplifies planning, attendance tracking, assessments, and certification issuance, helping teams easily meet regulatory and site-specific safety requirements. The platform enhances site security while ensuring real-time visibility of who is on-site and why by integrating with smart access control systems..

Inform, Align, and Aware: Animated Safety Induction for Modern Worksites

Animated Contractor safety induction solution provides an engaging, standardized onboarding experience for contractors, general workforce, and site visitors alike. Through visually rich, easy-to-understand, multi-lingual video, it clearly communicates critical information such as site-specific hazards, PPE guidelines, emergency procedures, access restrictions, and behavioral expectations. Whether it’s a short visitor briefing or a comprehensive contractor induction, animations ensure everyone entering the site is informed, aligned, and safety-ready—regardless of language barriers or technical background. This approach not only reduces reliance on live sessions but also improves knowledge retention, saves time, and reinforces a proactive, safety-first culture across the site.

A single goal guides our safety induction and awareness program: No harm to people and the environment. The video covers topics like being fit for work, health and hygiene, safe vehicle entry/exit and seatbelt use, pedestrian safety, working near live roads, required PPE and its correct use, participation in daily toolbox talks, site rules and discipline, housekeeping, heat stress, and fatigue control, open excavations, working at heights, safe ladder use, manual handling of materials and chemicals, use of hand tools and power tools, equipment and vehicle operation, key control, hot works, electrical safety, emergency response (injury, fire, spills), responsible use of resources (water, electricity), waste reduction and proper disposal. Above all, we promote the empowerment to work safely—and stop work when it’s unsafe.

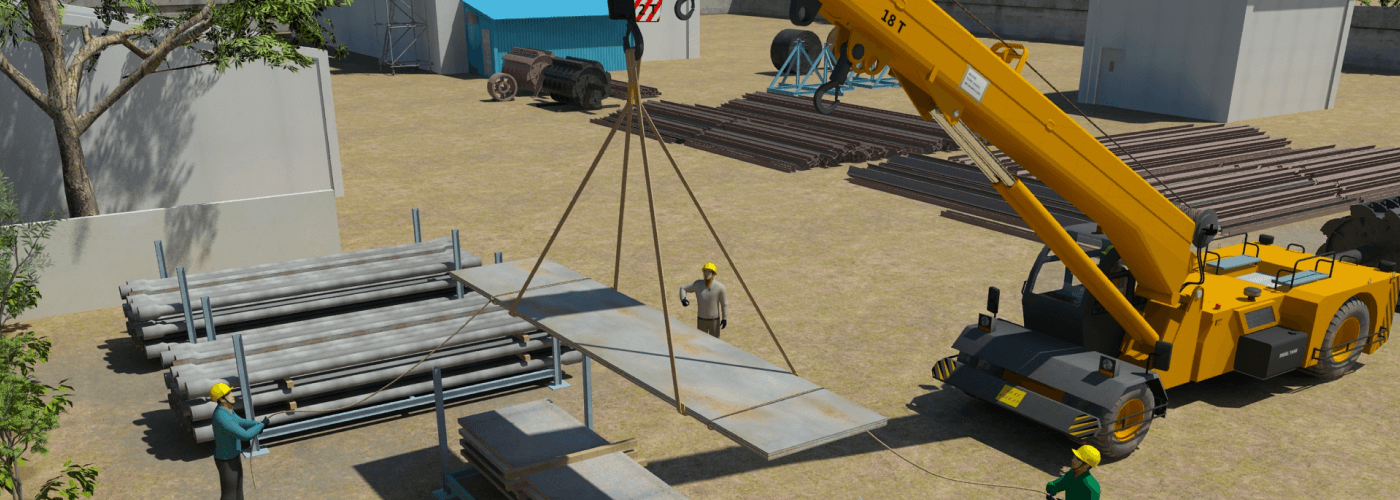

In the construction industry, high-risk activities such as working at heights, crane operations, excavation, and confined space entry present constant potential for serious incidents. Near misses and accidents—like a scaffolding collapse due to improper bracing or an electrical shock from unauthorized excavation—often stem from miscommunication, lack of situational awareness, or failure to follow safety protocols. Traditional incident reports and post-incident meetings frequently fall short of helping frontline teams truly understand what went wrong. With crews rotating across multiple phases and subcontractors entering and exiting daily, the opportunity to learn from past events is often lost in paperwork and technical jargon.

The Solution: 3D Incident Recreation for Smarter Safety Training

To truly reduce the recurrence of such events, organizations need to transform how they communicate safety lessons. Our 3D incident recreation solution brings real-life construction incidents to life, visually recreating the chain of events that led to failure. These immersive, scenario-based videos provide a powerful training tool that makes complex incidents easy to understand—regardless of a worker’s role, language, or literacy level. By turning lessons learned into compelling visual stories, teams are more engaged, risks are better understood reinforcing a proactive safety culture across all project-site levels.

We have developed 3D recreations for a wide range of real-life incidents and HSE lessons to raise awareness and prevent recurrence through powerful visual storytelling.. These include: Benzene leakage from tanker during loading, crane toppling in unit area, failure of a condenser davit arm, crushing of 440V charged armored electrical cable, failure of the chequered plate, acetic acid exposure, failure of tailing lug, forklift incident, hydraulic discharge trap impact injury, shell debris incident, flashover incident, and pneumatic fender explosion due to overfilling. Additionally, we have recreated critical construction and industrial safety lessons such as accident at BCU-13 conveyor take-up, transit mixer entanglement, working under live traffic, batching plant safety, crane material handling, crane toppling, and excavation collapse due to inadequate shoring, night work hazards, reinforcement-related incidents, road traffic risks, and electrocution during survey work, working at height, and working on or near water. Each scenario is carefully recreated to help teams visualize risks, understand root causes, and reinforce a proactive safety culture.

eLearning Tailored for Construction Teams

Our construction-focused eLearning solution empowers workers supervisors and engineers with flexible, on-demand access to training—anytime, anywhere. Whether on-site or in the office, they can engage with interactive modules that cover essential safety topics, best practices, and compliance requirements. We designed the platform with the unique risks and realities of the construction industry in mind, simplifying complex topics through visuals, assessments, and real-world scenarios. This digital approach boosts engagement and retention and helps companies build a safer, more competent workforce—while minimizing downtime and training costs.

“ TECH EHS developed the TATA Projects Safety Induction DVD with 3D animation and audio. This induction film explains various construction activities and the safety measures required to mitigate the risks involved.”

Tata Projects, India

P. Jagatheesan, AGM (EHS)

Closing Skill Gaps in Construction: Practical, On-Site Safety Training

In the high-risk environment of construction, a well-trained workforce is essential to ensure safety, prevent incidents, and meet regulatory standards. Our hands-on, on-premise training programs are designed to bridge critical skill gaps and build a safety-first culture across construction sites.

Key Training Modules Include:

Our programs combine real-world scenarios, instructor-led sessions, and practical exercises to help workers apply what they learn directly on the job. Whether you’re onboarding new workers or upskilling experienced teams, our training helps reduce incidents, improve productivity, and reinforce compliance with construction safety standards.

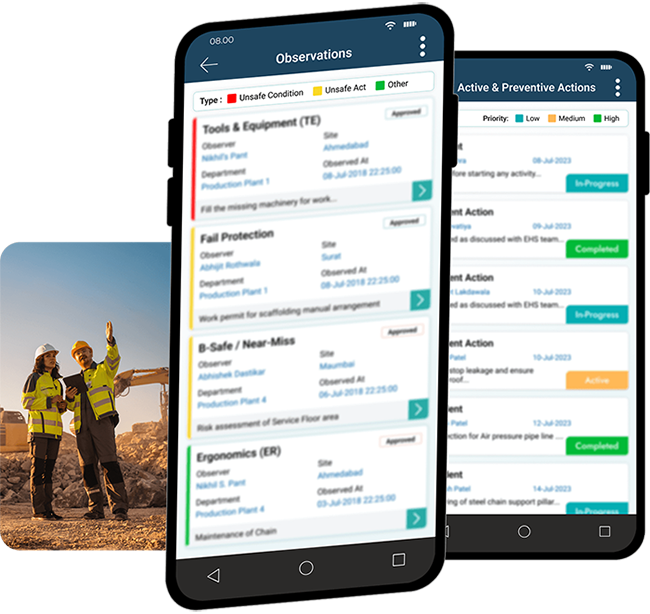

Maintaining visibility over day-to-day safety conditions becomes a major challenge in large-scale construction projects, where multiple contractors and teams operate across sprawling, high-risk zones. Critical observations—such as unsafe acts, hazardous conditions, or equipment misuse—often go unreported due to lack of time, accessibility issues, or unclear reporting channels. Without a structured method to log, track, and close these observations in real-time, there’s a heightened risk of near-misses escalating into serious incidents. The absence of timely follow-ups and closure of safety tasks, especially when spread across various zones and agencies, creates dangerous gaps in site safety and accountability.

The Solution: Log Safety Observations Using a Mobile App

Our field-ready mobile application simplifies safety observation reporting, allowing on-site personnel to instantly log unsafe acts or conditions—complete with images, videos, annotations, and location data using geo-tagging. We designed it for ease of use, even in low-connectivity areas, so it works online and offline, ensuring reporting never stops. Field users can quickly update non-compliance status, track assigned tasks, and follow through with Corrective and Preventive Actions (CAPA)—all in real-time. Field users can quickly update the status of non-compliances, track assigned tasks, and follow through with Corrective and Preventive Actions (CAPA)—all in real-time. Features like voice-to-text input, push notifications, and a clean, intuitive interface encourage higher reporting rates and faster response times. With built-in analytics and observation history, teams can identify patterns, gain actionable insights, and make informed decisions—ultimately building a safer, more responsive job site every day.