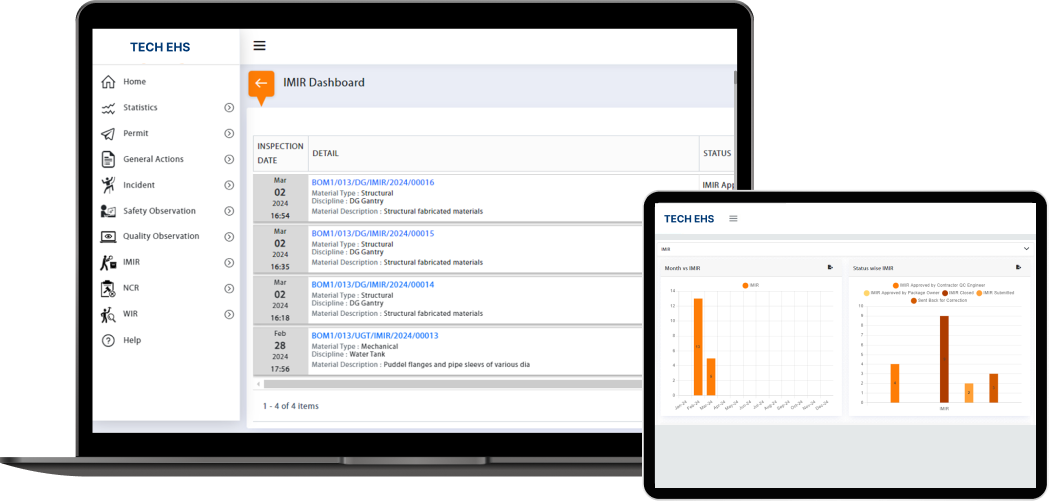

Incoming Material Inspection

Ensure quality integrity with our vigilant incoming material inspection solution

Before construction or production can begin, the supplier’s incoming goods must be inspected to make sure they match the specifications of the original instructions. A few faulty inputs could ruin production and could cause the creation of faulty results. These issues can cause delays, as the end result may not be correct and now you must take the time to reorder the goods and begin the entire process again.

With our system, every material can be inspected with a well defined checklist. Hence you will be able to ensure efficiency and compliance with quality standards. Thus our robust incoming material inspection solution can contribute to overall quality assurance and customer satisfaction.

Features

Configure inspection checklists

Record Incoming Material Inspection

Review IMIR

View IMIR records & insights

Digital transformation for your Safety operations With Flexible Robust Solution That supports

Our Success Stories

Delivering Secure Connected Digital Experiences

A Global Lifesciences Company

An established shipyard in Las Palmas

Leading CNG Gas Provider

Inspiring Stories

Testimonials from Industry Pioneers

TECH EHS has been a great partner in accelerating and elevating our EHS journey. With “a click of a finger,” the platform could retrieve and present any useful information or data. Additionally, the mobile application provided ease of use for anyone to record any incident or observations for further investigations instantly. Their expertise and commitment to our needs have been evident in delivering solutions through the software and support rendered. We appreciate their continuous efforts to improve the software and adapt to our evolving needs.

TECH EHS Team is knowledgeable in solving and giving suggestions to the E-PTW and WMS system that we worked with. They illustrate the benefits of using the e-system and give us confidence to continue the business with them. We have a new experience to work together with suppliers overseas and are glad to manage the time well and able to complete the projects on time. We appreciate and value your support and service. Looking forward to having the next project soon!

We were looking for a competent solution for our scaffolding operations spanning multiple sites. Scaffolding management system offered us the ability to shift from a basic to digitalised all-in-one platform.This has enabled efficient scaffolding operations providing inspected and safer material, effortlessly. What helps our case even more is the software availability in local language (Chinese) and English.

We needed a customized solution, as the sheer scale of our operations demanded accurate estimates of scaffolding equipment and manpower. Older methods resulted in significant time delays in scaffolding operations. Through our close discussions, TECH EHS proposed a workflow for SMS that fitted the bill, perfectly. Ultimately, this led to an overall reduction in delays and a streamlined scaffolding lifecycle.

It was a wonderful journey with TechEHS team from past 4 years and I am recommending TechEHS software tool to everyone for effective implementation of EHS Management system. We appreciate entire team of TechEHS for their co-operation and respond to our queries very quickly.

CGPL Mundra is first UMPP of 4000 MW that has been commissioned in the shortest duration of one year and “permit to work system” was one of the challenge for safe work culture. TECH EHS’s tailor-made EPTW system which could be developed as per the organization safety guidelines has provided us ultimate solution. We got an excellent and prompt support from TECH EHS throughout. This system has exhibited all essential features of company safety guidelines and can be established in other divisions of the company. Thanks!

One of the advantages of awarding the contract to TECH EHS is that they have expertise in the field and they are easily able to understand our requirements with very minimal consultation. It would be easy for us to roll out the projects within the stipulated time. We have partnered with TECH EHS for many animation projects, software project and continue to use their services to this day. The net result of our association has been very fruitful and productive. Keep it up TECH EHS!

We are very happy to have implemented software developed by TECH EHS. On field staff (ground level supervisors) is comfortable using it as it has been customized to adapt easy work-flow. We recommend their services to anyone looking for software services. Reporting was a key challenge and they addressed this through reporting measures through graphic charts and analytical trends. This reduced time spent over meetings. We are quite grateful to TECH EHS for providing such a solution and would look to continue this partnership in future also.

TECH EHS has provided Employee ID Badging Software & Onsite Manpower solutions to IOCL. We state that your Team is providing the best services to our Corporation. We have no complains till date and are satisfied. The entire process is very simple and hassle-free. They also maintain the deadlines and no unnecessary follow-ups are required. We wish TECH EHS Good Luck….! Keep it up….!

Our Clients