Table of Contents

Introduction

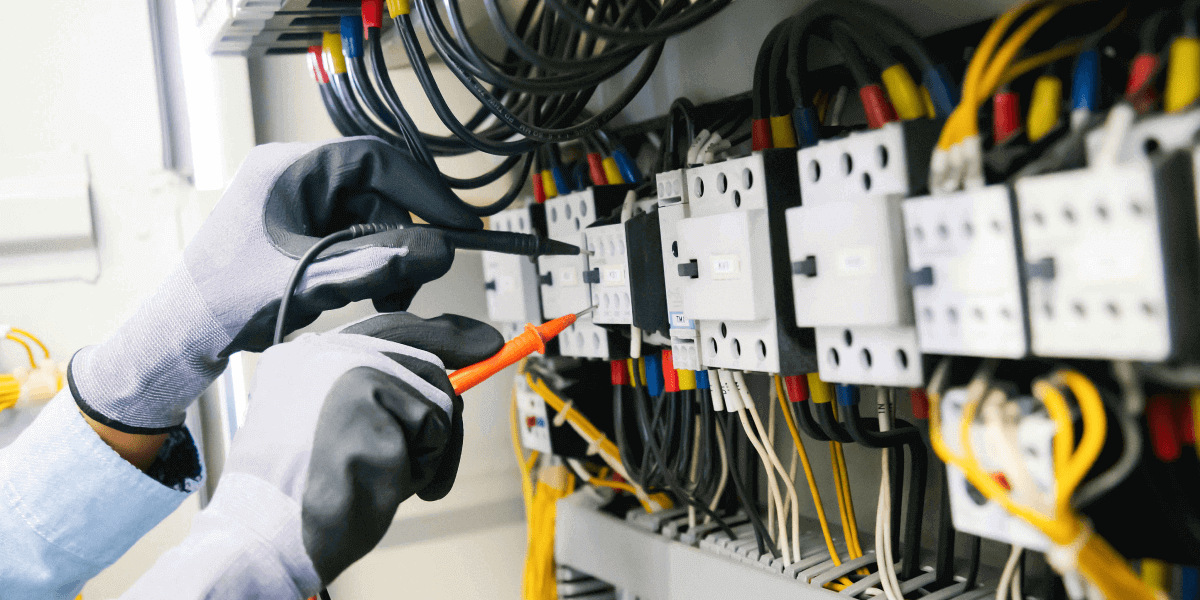

A Standard Operating Procedure is a set of instructions for a specific task or process. In the case of electrical management and maintenance, an SOP electrical can help you and your team stay organized and efficient when it comes to keeping your electrical systems running smoothly. Streamlining your Standard Operating Procedure (SOP) for electrical maintenance department involves optimizing and simplifying the processes to ensure efficiency, safety, and compliance.

Are you an electrical manager tired of constantly putting out fires (metaphorically speaking, of course)? Or maybe you’re just starting in the industry and want to avoid any literal sparks flying in your face?

Either way, a well-written SOP for the electrical maintenance department can keep your electrical systems in tip-top shape.

First, let’s define what an SOP is. It’s basically a set of instructions on how to carry out a specific task or process. In the case of electrical management and maintenance, an SOP can help you and your team stay organized and efficient when it comes to keeping your electrical systems running smoothly.

A comprehensive SOP for electrical maintenance department is essential to prevent breakdowns, extend the life of electrical equipment, and most importantly, ensure the safety of workers.

Standard Operating Procedures (SOPs) are a crucial component of an effective electrical management and maintenance program. SOPs help ensure that procedures are followed consistently, and that risks and hazards are minimized.

By implementing comprehensive SOP electrical maintenance department, organizations can reduce downtime, extend the life of electrical equipment, and, most importantly, ensure the safety of workers.

Looking for engaging ways to train your electrical team? Explore our animated safety videos designed to improve training efficiency and safety compliance.

Best Practices for Implementing SOP Electrical Maintenance

To ensure effective implementation of an electrical maintenance procedure, organizations should:

In Conclusion

An effective SOP for electrical maintenance department is crucial for ensuring safety, equipment longevity, and minimizing downtime. Organizations can create a safer and more efficient work environment by streamlining standard operating procedure for electrical work.

SOPs should be regularly reviewed and updated to reflect changes in equipment, technology, and regulatory requirements.

A commitment to ongoing training and record keeping helps ensure that workers handle the operation and maintenance of electrical equipment safely and effectively. With a comprehensive electrical standard operating procedure in place, organizations can minimize risks, extend the life of electrical equipment, and most importantly, ensure the safety of workers.

So, don’t let your electrical systems give you a shock! Stick to the SOP electrical and keep the sparks flying in the right direction.

Remember, in the world of electricity, safety always comes first.

Transform your safety training programs with impactful animated safety videos that simplify complex procedures and enhance comprehension.