In the power and utility sector, where high-voltage systems, hazardous energy sources, and critical infrastructure are part of daily operations, managing safety during maintenance, shutdowns, and project work is non-negotiable. Manual Permit to Work (PTW) systems—still commonly used across substations, generation plants, and field sites—present serious challenges in coordination, compliance, and risk management.

Paper-based permits often lack real-time visibility, centralized control, and integration with isolation procedures. This can result in unauthorized work, missed Lockout/Tagout (LOTO) steps, delayed approvals, and poorly coordinated activities. Without robust isolation management and cross-functional communication, the likelihood of energy release incidents, SIMOPS (simultaneous operations) risks, and safety breaches increase significantly.

Digital PTW for Power & Utilities: Enabling Safer, Smarter Operations

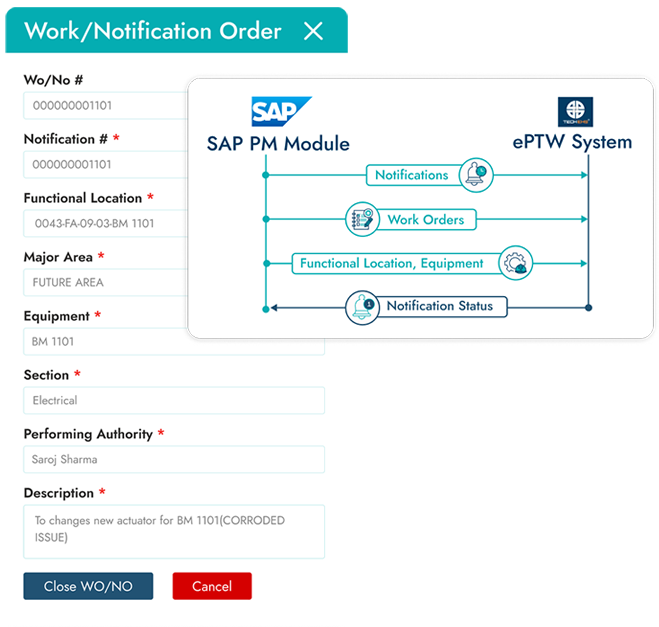

Our Digital Permit to Work solution is purpose-built for complex, high-risk environments typical in utility operations. It digitizes the entire PTW lifecycle—from initiation and risk assessment to isolation tagging, approval workflows, job execution, and closures ensuring complete control and traceability at every step.

Key features include:

By automating PTW processes and linking them directly with safety protocols, our system minimizes paperwork and subsequent delays, enhances accountability, and ensures that no work begins without the proper controls. Teams can instantly view permit dependencies, monitor isolation points, and verify that all safety preconditions are met before work is executed.

For utility providers operating under strict compliance requirements and tight service-level expectations, our PTW system helps enforce safety at scale—while reducing downtime, improving planning, and building a stronger safety culture.

Because in the power sector, where every switch, circuit, and connection matters, safe work must be authorized, visible, and controlled at every level.

Coastal Gujarat Power Limited (A Tata Power Company), India

Umesh Likhite, Group Head – Operations

The permit-to-work system at CGPL Mundra presented a critical challenge in enabling safe work. TECH EHS developed a tailor-made EPTW system that complied with the organization’s safety guidelines, making it an ideal solution.

In the power and utility industry, where operations span high-risk environments, from generation plants and substations to field transmission and distribution, the need for a comprehensive, scalable EHS management system is critical. Excel-based or siloed systems often lead to delayed incident reporting, missed inspections, incomplete corrective actions, and increased exposure to regulatory penalties and operational risks.

Smart EHS Management for Power & Utilities: From Compliance to Culture

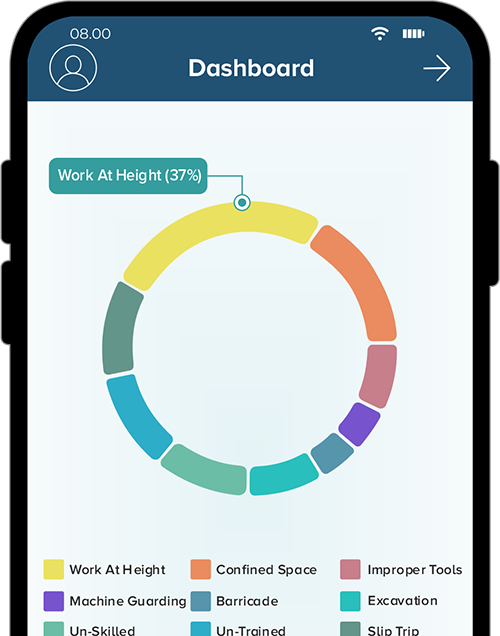

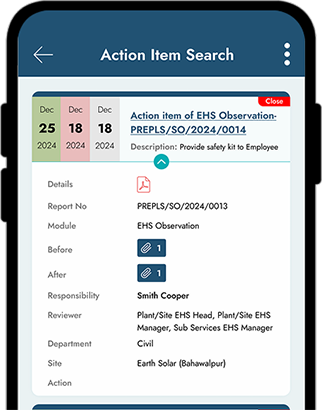

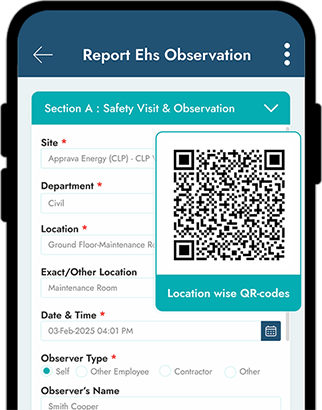

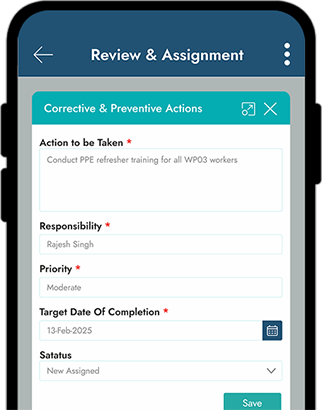

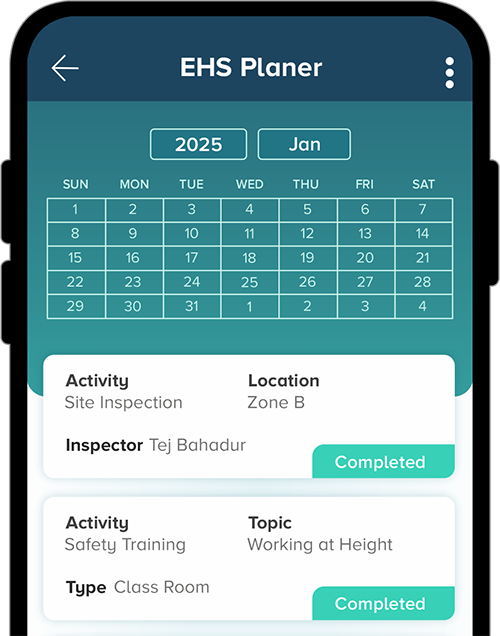

Our EHS management software is built to meet the complex safety demands of utility environments, helping organizations align with international safety standards such as ISO 45001, and ISO 14001. The platform offers real-time, mobile-enabled tools for incident and hazard reporting, equipment inspections, behavior-based safety (BBS) observations, and audit readiness—ensuring that safety isn’t just documented, but practiced.

With integrated modules for:

The platform helps to enforce consistent safety standards while adapting to local conditions and site-specific risks. Through SAP integration, corrective and preventive actions (CAPA) can be tied directly to SAP maintenance orders to automate other workflows like equipment maintenance, material procurement —automating the requisition of appropriate PPE, tools, or equipment based on investigation outcomes.

More than just a compliance tool, our solution is designed to transform safety culture. By encouraging participation from field teams, supervisors, and leadership, the system supports a shift from reactive safety to proactive engagement. The solution empowers employees not just to follow procedures but to take ownership of safety outcomes.

With complete visibility of the EHS performance across sites, better audit readiness, and data-driven insights, utility providers can build a safer, smarter operation—where safety is more than a policy; it’s a shared commitment.

Mobile App Solutions for Safer Power Operations

eLearning for Power & Utility Teams

Empower your workforce with on-demand, role-specific training designed for the unique risks of the power and utility industry. From electrical safety and isolation procedures to compliance and emergency response, our interactive modules simplify complex topics through real-world scenarios and visuals.

Accessible anytime, anywhere, this digital solution boosts safety, improves retention, and reduces training downtime—helping build a skilled, compliant, and confident workforce.

Emergency Preparedness

Power and utility operations face critical emergencies like transformer explosions, grid blackouts, fuel leaks, and control room fires, which require rapid, coordinated action to prevent cascading failures. Accurate information during such critical moments is vital for effective emergency management.

Organizations must regularly validate emergency plans through emergency preparedness inspections, mock drills, and gap identification, with proper tracking of corrective actions and closure statuses. The efficiency with which these processes are executed often determines how well they contain emergencies with minimal impact.

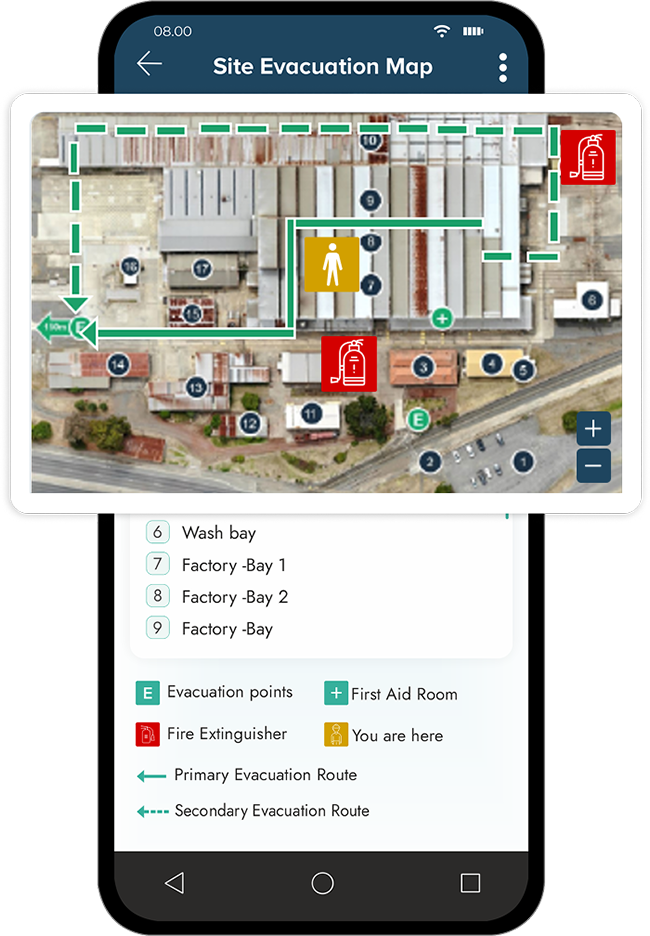

A digital system supported by a mobile app significantly enhances the ability to manage these tasks effectively and in real-time.

Empowering the Power Industry: Safety Training Workshop

Industry Challenges in Power Plant Safety

The power industry operates in a high-risk environment where workers routinely face high-voltage equipment, confined spaces, mechanical lifting, and hazardous energy sources. Despite strict protocols, gaps in hazard awareness, inconsistent risk assessments, and ineffective incident reporting continue to pose significant safety and compliance challenges.

Training Objectives

This workshop aims to improve safety awareness by helping participants identify workplace hazards and adopt a proactive safety mindset. It provides practical training in HIRA, JSA, and incident reporting through hands-on exercises and real-world scenarios. Participants will learn to assess and prioritize risks, apply control measures, and report incidents accurately. The program also shows how to integrate HIRA, JSA, and incident investigation processes into a unified safety system that supports continuous improvement.

Expected Outcomes

Participants will gain confidence in managing risks and applying safety tools effectively. The training is expected to reduce incidents, strengthen the safety culture, and improve regulatory compliance. It also lays the groundwork for continuous safety improvements and better cross-functional safety coordination.

Highly Engaging and Insightful

“ The 3-day HIRA/JSA workshop conducted by TECH EHS provided a comprehensive understanding of hazard identification and risk assessment. The practical exercises and real-life case studies made it engaging and applicable to our day-to-day operations. The 2-day Incident Investigation workshop was equally impactful, teaching us structured approaches to prevent future incidents.”

Govindnath Tiwari (Safety Head, TATA Power)