Our team crafted comprehensive solutions for every intricate challenge. Tailoring each solution to meet their specific requirements, we implemented systems that generated emails and notifications at regular intervals, ensuring timely task completion and communication at every level.

The organizational hierarchies required unique integration. Our team developed a solution such that conventional energy had the primary fields, and renewable energy required the remote location details as an add-on on the same UI.

As network access in remote locations was very limited, we integrated offline access into the safety system. This made real-time tracking possible and accelerated all the processes.

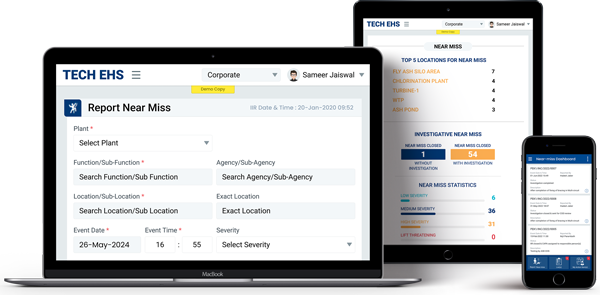

Integrating digitalized safety solutions proved valuable in generating, saving, and amplifying safety processes in the respective energy sectors. The consolidated data center with an interactive dashboard ensured easy access to data. All the files could be exported easily for slides, reports, or analysis generation.

We designed almost 15 safety modules that generated different forms for conventional and renewable energy with the same feeds. However, the two modules, CAPA and HIRA, required particular attention. For example, the HIRA form had different forms for both energy sectors; Therefore, the necessary form was generated to select the specific choice.

Our team designed the CAPA module to strictly require the concerned person to record the pictures and fill in the comments as per the action plan. Once the images were clicked, the system auto-generated the longitude and latitude of the images’ location.

With the integration of a mobile app, real-time tracking became easy. It was a two-way street for checking, updating, and escalating safety issues.

The entire digitized safety system solved the problems of the conventional and renewable energy sectors by generating different forms, streamlining processes, and maintaining a centralized platform for data.