Table of Contents

Introduction

What is Industrial Housekeeping? Is it the same as generic housekeeping?

Let us find out more.

What Is Industrial Housekeeping?

Surprisingly, housekeeping in industrial safety appears to be the most doable of safety initiatives. Nonetheless, despite their simplicity, many industrial concerns suffer from poor housekeeping. The most common reason for failing to keep a clean workspace is a lack of time.

“We’re too busy,” or “there’s not enough time to clean,” workers frequently say.

In today’s highly competitive environment, keeping workplaces in tip-top shape is more important than ever.

Despite this reality, most businesses struggle to retain talent while also providing a safe, productive, and satisfying workplace. Good industrial housekeeping expedites production protects workers, boosts morale, and increases profitability.

Profitability is the goal of industrial housekeeping. Similarly, a clean, organized workplace produces happy, productive teams and environments.

Ready to improve your workplace? Explore our industrial housekeeping solutions today!

Importance of Housekeeping in the Industry

A productive workplace

When time is money, one should owe it to one’s own bottom line to be highly efficient. A clean, well-organized workspace is essential for teams to focus on results.

Let’s face it: we all waste too much time looking for things because they are easily misplaced, or we become complacent and don’t think about where they should go, especially when we need them quickly. For maximum efficiency, we must sort and organize our items methodically.

Construction and manufacturing housekeeping in industry initiatives are so crucial that they affect the industry’s overall productivity and downtime.

A crew that spends any time looking for tools, materials, or supplies, or worse, suffering productivity loss due to an injury, is not adding value to the company or our clients.

Looking for a cleaner, safer workplace? Let our industrial housekeeping services help!

Wellness and Health

The statistical data on financial loss resulting from workplace trip-slip-and-fall incidents is staggering! This is primarily due to the additional hazards created and the types of injuries in a complex, messy, dangerous environment. Slip hazards are created by dust piles and oily surfaces.

Loose materials and tools create unnecessary trip hazards. As a result, a slip or trip is more likely to result in a fall, which can result in a significant back or head injury or, worse, a fatality.

Again, housekeeping in industrial safety is more than just being “clean.” It is also about being safe.

How to Improve Housekeeping in the Workplace

Create a Team

Our financial success is directly related to our team’s engagement and satisfaction. They come to work hoping to accomplish something and be successful. They are dissatisfied with the amount of time wasted managing.

A cluttered workspace is a distraction that will affect our ability to deliver great products and retain a great team.

This roadblock to success is entirely avoidable and saves time.

On the plus side, when crew members see a consistently polished site and know they can rely on their teammates to take care of shared tools and spaces, our teams become a source of pride for both the individuals and the firm.

Housekeeping is about keeping things clean! Some benefits of good housekeeping practices in industry include creating a satisfying workplace, which fosters trust and engagement among team members and helps to retain talent.

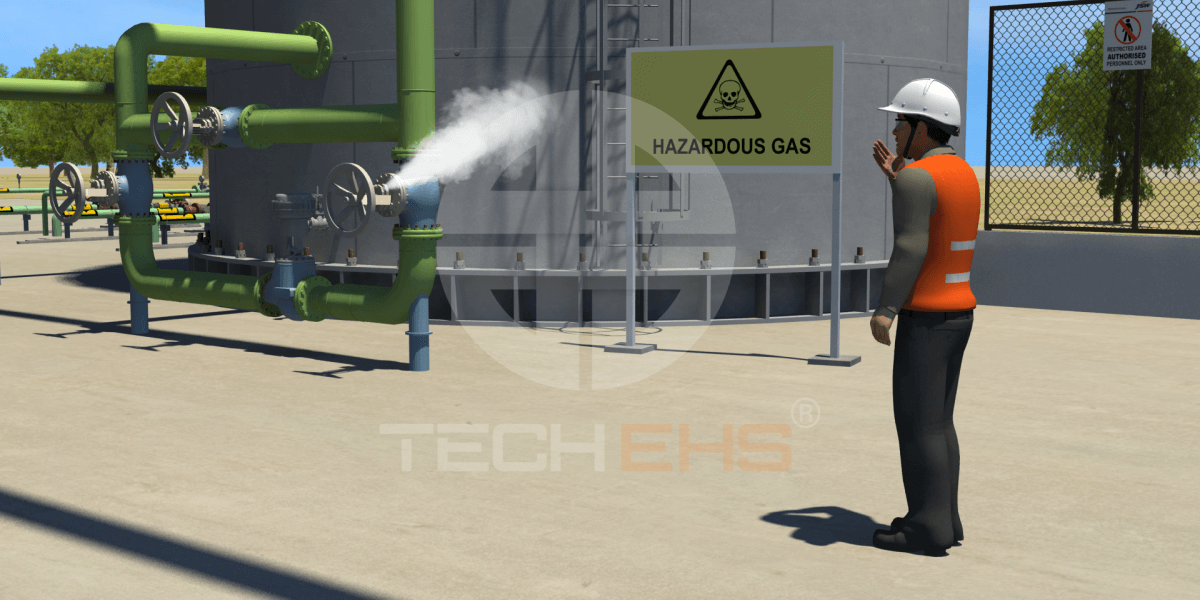

When extreme gravity is explained through animation videos, people tend to subconsciously imitate the behavior as it seems self-explanatory.

Here’s an example –

The Japanese 5S system can be considered a forerunner to industrial housekeeping. The five s’s are seiri/sort, seiton/straighten, seis/shine, seiketsu/standardize, and shitsuke/sustain, respectively. Toyota invented the 5S in the 1960s, and it has since become an international standard method for workplace organization, particularly in the manufacturing industry.

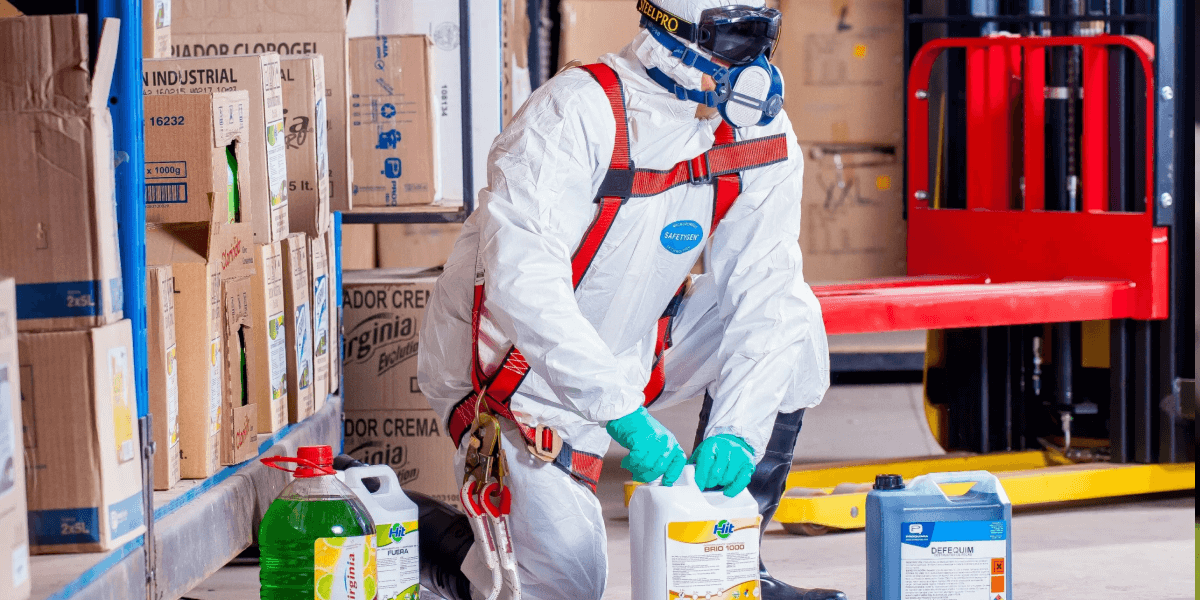

While keeping things tidy and neatly organized is essential, the primary goal of industrial housekeeping is to have a system that reduces the amount of dangerous dust, particles, fumes, and other emissions within a facility. Exposure to these substances is frequently indirect and can affect far more people than just the operator of a particular machine.

Consider the welding industry, where protective clothing, helmets, and other equipment have long been a safety standard for most welders.

However, a much more recent discovery is the danger posed by welding fumes to a broader range of people, such as visitors and less protected co-workers

Advantages of Industrial Housekeeping

The advantages of industrial housekeeping are numerous and must be emphasized.

Conclusion

Nonetheless, the overall trend is clear: industrial housekeeping is becoming more common, corresponding to a broader, global trend in which industries and facilities are becoming safer and more sustainable.

New technology in the housekeeping industry and stricter emissions and safety regulations have resulted in more common and technologically advanced industrial housekeeping.

Our TECH EHS animation videos mention this critical aspect: “Housekeeping is not an “additional” service; it is a successful business strategy. It is also the foundation for daily safety and productivity aspects.”

Explore our industrial housekeeping checklist and check out how our unique solutions can help streamline your operations. Good housekeeping practices in industry don’t just keep your workplace clean—they create a safer, more productive environment. Are you prepared to move forward? Visit our product pages and see how our services may transform your facilities!