Table of Contents

Introduction

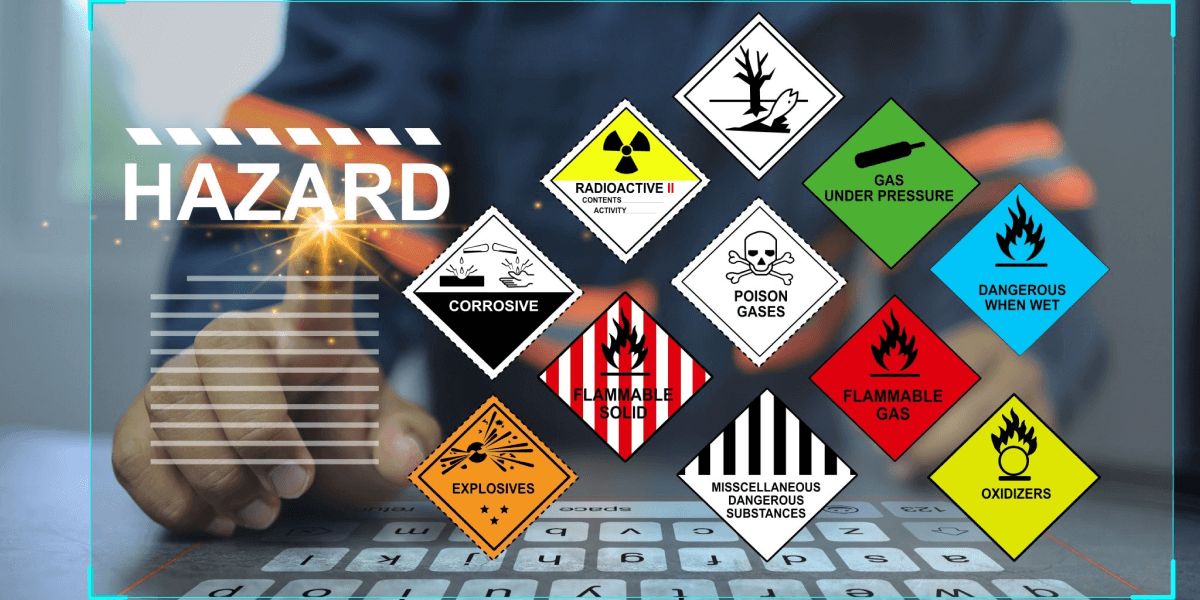

In the chemical sector, process understanding and clarity is extremely essential. Even a small mistake can have disastrous effects. According to the Center for Chemical Process Safety (CCPS), a significant number of process safety incidents are caused by workers’ inadequate understanding of the procedures they are responsible for. Traditional training methods struggle to fill this gap. Thus, employees are left unprepared for obstacles they may face in the workplace.

For example, suppose a chemical company in the UAE handles hazardous substances such as hydrofluoric acid. Without the proper visualization tools, workers frequently find it challenging to detect important risk indicators. Thus, the possibility of accidents increases.

In such cases, PFDs offer an effective solution. They function as visual aids as well as practical safety tools. PFDs provide practical understanding and technical proficiency to workers when used in training. They can make strategic decisions if they have a comprehensive awareness of each process’s workings and potential hazards. Additionally, they can respond to irregularities and prevent situations from getting worse. In high-stakes scenarios like chemical factories, this kind of clarity is crucial because it can save lives and develop a culture of safety in the organization.

What Are the Best Practices for Using PFDs in EHS Training?

As a trainer, these are some ways you can use PFDs for EHS training in chemical industry:

Simplify Engineering PFDs for Training

You must focus on flows, interlocks, and hazard zones to make diagrams more accessible.

Example: In a sulfuric acid production plant, color-code acid flow paths in red. Also, indicate relief valves to highlight critical areas.

Use Scenario-Based Visuals

Always ensure that diagrams are overlaid with animations to illustrate system behavior during abnormal events.

Example: Suppose you are a trainer in a hydrogen reactor. You animate a blocked hydrogen gas line to demonstrate pressure buildup and the activation of a safety valve.

Incorporate Real-Life Case Studies

You can incorporate real-life case studies as a best practice by linking training diagrams to past incidents. This helps reinforce lessons learned and improve retention.

Example: To show how to prevent an overheat event in a nitric acid line, you can highlight the control valve failure that led to the overheating.

Incorporate Real-Life Case Studies

You can use the same PFD but create role-specific learning paths.

Example: For a solvent recovery unit, you must ensure:

Embed PFDs into Digital Learning Platforms

You can integrate PFDs into e-learning modules for continuous training.

Example: In a chlorine bottling plant, trainers can link the PFD to monthly safety drills and operator checklists for ongoing reinforcement.

Conclusion

It is now essential to incorporate PFDs into regular EHS training to foster a proactive safety culture. PFDs ensure that workers become used to safety. Moreover, it helps visualize procedures, recognize risks, and plan for emergencies.

Are you prepared to improve your EHS training? Collaborate with TECH EHS to implement innovative solutions tailored to your sector.