Table of Contents

- Introduction

- Chemical Management Best Practices

- Gather crucial supply chain data.

- Develop relationships with selected vendors.

- Better inventory management

- Control and minimize hazardous waste

- Do the math and re-engineer the process.

- Consider purchasing information management systems.

- Chemical Management Best Practices

- A Focus on Chemical Safety

- Policies for Chemical Management

- Chemical Restriction Testing

- Supplier Administration

- Materials Purchasing

- Training Chemical management training for internal teams is essential.

- Auditing

- Future-Readiness

- Conclusion

- Frequently Asked Questions(FAQ)

Introduction

Chemical management companies that want to manage chemicals more efficiently must now make investments in technology that makes data administration and use easier. The chemical industry’s most recent technical advancements offer sophisticated data operations and reporting capabilities. These developments have also facilitated data interchange between chemical businesses and outside parties like suppliers and vendors.

If one must talk about any challenges ahead in chemical industry management, one can mention about –

Industrial and laboratory operations managers frequently confront formidable obstacles when complying with environmental requirements and managing chemicals efficiently.

Chemical firms’ total costs are more than purchase prices; they also account for costs associated with inventory management, safety, compliance, and disposal management. Chemical purchases are frequently handled similarly to other purchases by businesses. However, these businesses disregard or fail to account for these hazardous items’ special handling, reporting, and disposal needs. Ignoring these aspects and using an ineffective chemical management strategy can eventually become unsafe and expensive for chemical enterprises.

We outline a few best practices that businesses must follow for effective industrial chemical management in their organizations.

Chemical Management Best Practices

Gather crucial supply chain data.

Chemical management companies must incorporate environmental health and safety into their processes to ensure proper chemical management within the business. The Environmental Management Information System (EMIS) should receive and store the data generated, gathered, and modified through vendor systems. The work required to gather and manage suitable data may appear challenging initially, but it will undoubtedly be worthwhile in the long term.

Develop relationships with selected vendors.

This method is one of the finest ways to bargain prices, standardize goods, and guarantee timely delivery. For chemical management companies, keeping good relationships with the vendor provides benefits beyond merely cost reduction. They also make it easier to simplify material evaluation, lower administrative costs by using electronic payments, and make vendors more reliable providers of market data.

Better inventory management

Inventory management is one of the most important components of chemical management for businesses. The best option to ensure precise chemical inventory is specialized inventory management software or an online application. These systems must link with suppliers, purchasing systems, or internet retailers to maintain dynamic inventory data. Chemical inventories have unique information and availability requirements; hence, it is advised to collect this data electronically from the original source at regular intervals.

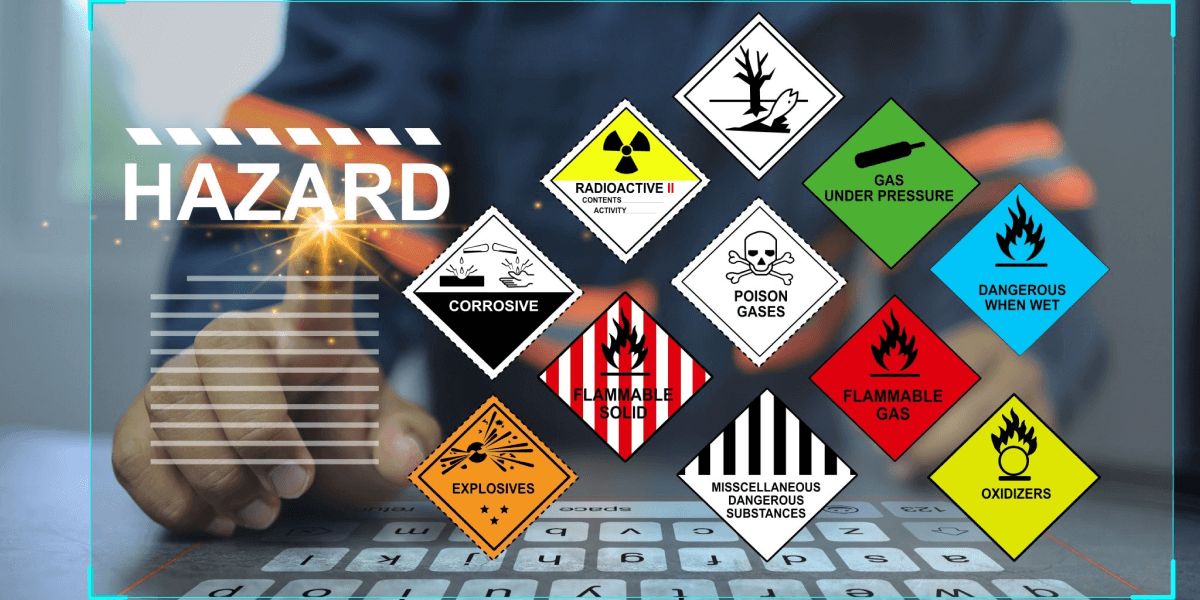

Control and minimize hazardous waste

Businesses must first try to reduce trash to ensure cost savings in waste disposal. One of the most expensive expenses related to chemical management is waste disposal. such a degree that it occasionally even exceeds the price of buying chemicals. Process review and a comprehensive awareness of the expenses related to hazardous waste disposal are needed to find cost-saving opportunities and ensure improved chemical management in the business.

Do the math and re-engineer the process.

Making improved procedures or less dangerous replacements may be made possible by totaling the costs related to chemical management and assessing the products in terms of waste minimization. Expanding the role of chemical suppliers beyond the straightforward sale and transportation of chemicals to include managing the customers’ on-site products is a developing trend in chemical management.

Consider purchasing information management systems.

Chemical management companies that want to manage chemicals more efficiently must now make investments in technology that makes data administration and use easier. The chemical industry’s most recent technical advancements offer sophisticated data operations and reporting capabilities. These developments have also facilitated data interchange between chemical businesses and outside parties like suppliers and vendors.

Chemical Management Best Practices

A Focus on Chemical Safety

Policies for Chemical Management

Chemical Restriction Testing

Supplier Administration

Materials Purchasing

Training Chemical management training for internal teams is essential.

Auditing

Future-Readiness

Conclusion

The appropriate management of chemicals is a fundamental component of sustainable business practices, and retailers are instrumental in advancing supply chain initiatives and regulations that ensure dangerous chemicals are eliminated from the supply chain. All the above and more can be achieved if chemical management companies invest in EHS chemical management software. This software promises more than just effective chemical management. It escalates workplace safety while ensuring chemical management best practices.

Chemical management companies must ensure the use of best practices. This proactive approach ensures a safe and sustainable future for the employees, their health, and the environment.