Table of Contents

- Introduction

- The Challenges with Traditional SOP Training

- How Animated SOPs Revolutionize Hazardous Chemical Training

- Key Elements of an Effective SOP for Hazardous Chemicals

- The Future of SOP Training in the Chemical Industry

- Conclusion: The Future of SOP Training in the Chemical Industry

- Frequently Asked Questions(FAQ)

Introduction

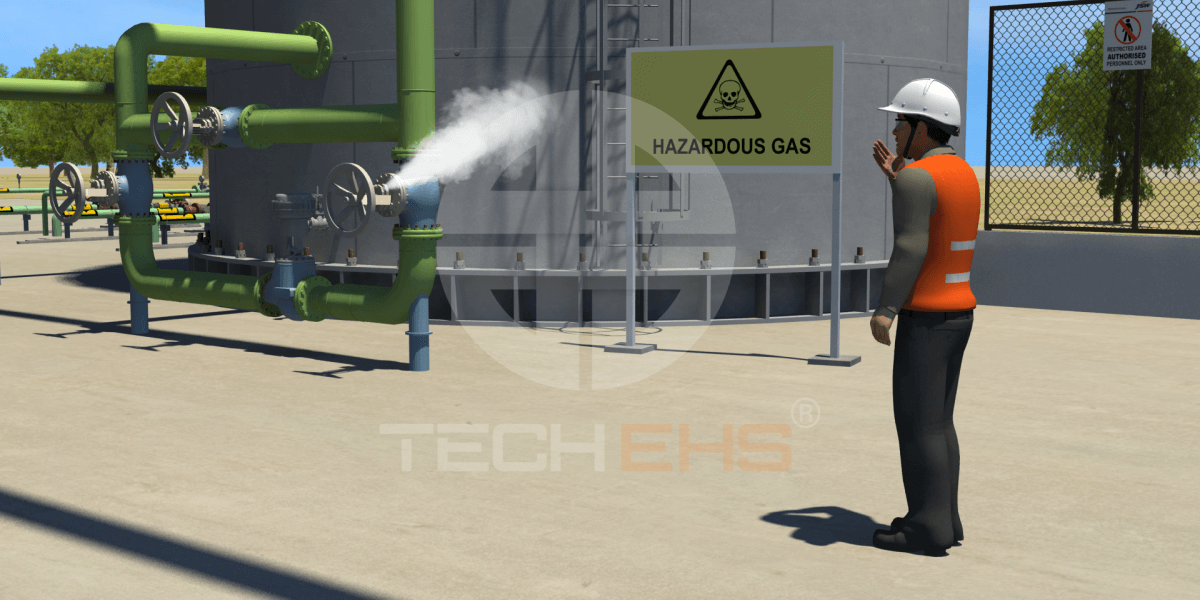

Managing dangerous substances carries a lot of risks. Accidents, fires, or even major industrial catastrophes can result from a single error. As per the statistics issued by the U.S. Bureau of Labor, around 10% of all occupational injuries each year are caused by chemicals.

Do you want to lower these occurrences?

According to OSHA, implementing clear and concise Standard Operating Procedures (SOPs) is the solution. It is one of the most significant strategies for reducing chemical-related workplace mishaps.

Traditional SOPs are usually text-heavy documents. Employees either skim through them or completely disregard them. However, when working with hazardous chemicals and compounds, skipping even one step might have disastrous consequences. To ensure safety compliance and the retention of essential information, animated training for SOPs is a game-changer.

The Challenges with Traditional SOP Training

Here are some challenges that employees face with traditional SOP training:

How Animated SOPs Revolutionize Hazardous Chemical Training

Key Elements of an Effective SOP for Hazardous Chemicals

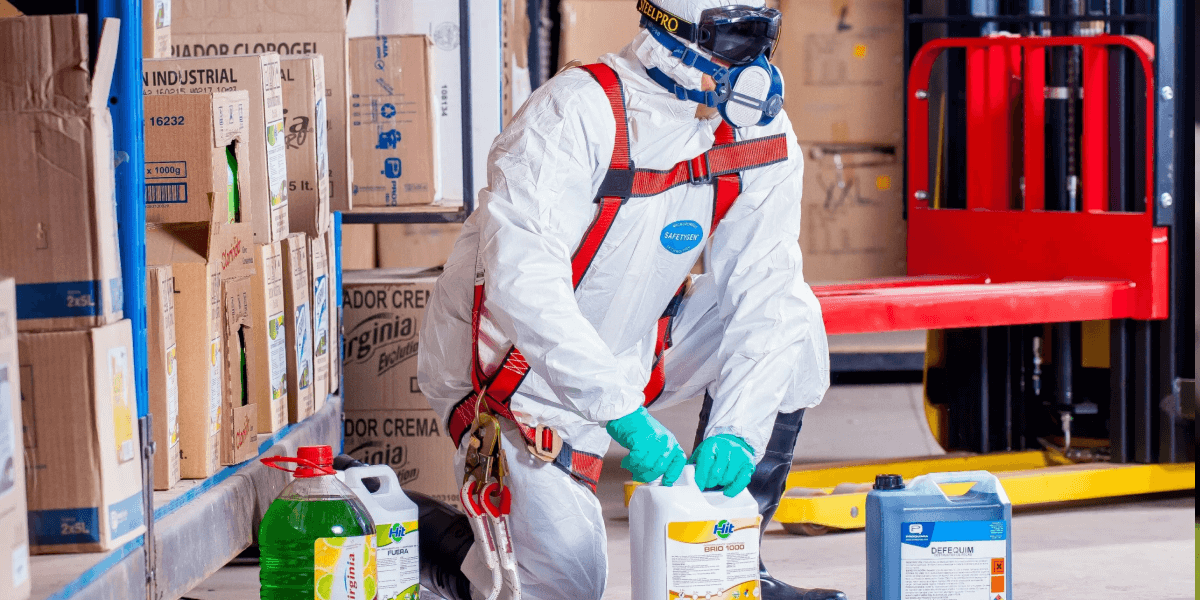

Animated training for SOPs makes hazardous chemical training more engaging and easy-to-follow. They provide a contemporary, efficient method to improve workplace safety. Consider a Singapore-based chemical plant that introduces gamified safety training. They observed that 90% of employees completed the program within the first month.

Here are the key elements that make an SOP truly effective:

Conclusion: The Future of SOP Training in the Chemical Industry

Traditional SOP training methods struggle to ensure workplace safety anymore. Animated SOPs provide an engaging, effective, and scalable solution. When presented with videos, employees retain 95% of the information. However when they read text, they only retain 10% information. The animated videos train the employees in hazardous chemical handling. Moreover, they provide real-world scenarios, interactive simulations, and mobile accessibility.

For chemical manufacturers and industrial plants looking to modernize safety training, cutting-edge animated SOPs offer the ideal solution. They help ensure employees are well-prepared, reduce accidents, and enhance workplace safety.

Want to transform your SOP training? Explore digital training solutions today!