The work environment can be a perilous climate, particularly in a modern setting. In 2017 alone, there were 2.9 million non-deadly wounds in the work environment. While that number is down somewhat from years past, lessening working environment mishaps – reducing the causes of accident in industry remains a key safety goal for many organizations.

Envision strolling into your plant one Monday morning to observe the light over your workspace has blown over the course of the end of the week.

No biggie, you think.

You choose to report it toward the finish of the shift and approach setting up your work for the rest of the day.

Following a couple of hours, you notice that your shoulders are somewhat sore yet credit it to the snow you needed to scoop over the course of the end of the week.

You are not even mindful of the abnormal bumped act you’ve placed yourself to view and best-see the drill area that likely causes you discomfort!

Following a couple of additional hours, you conclude you want to loosen up your back and have some time off to rub your shoulders and throbbing lower back. Following a couple of moments, you feel a touch of help. In any case, because of the dull workspace, you don’t understand that you haven’t, as expected tied down the metal to the press while returning to your station, and before you know it, the metal leaps up, cutting your hand and arm, requiring many stitches.

Mishaps like the one portrayed above are very common. Often workers don’t relate small issues with injuries—but these are real causes of industrial accidents that escalate quickly if ignored.

Nonetheless, had the worker taken time to demand a bulb change toward the beginning of a shift, the aggravation in his shoulders and back might have been kept away from. Plus, he would have had the option to plainly see the metal had the space been brighter. It’s small proactive steps like this that reduce industrial disaster causes in real-time.

Let’s discuss Certain Causes of Industrial Disasters

Industrial accidents can have devastating consequences for workers, their families, and the surrounding community. Understanding why do industrial disasters occur is crucial to preventing future mishaps. Here are a few major causes of industrial accidents:

1. Atmospheric Causes of Industrial Accidents

Mishaps that happen from ecological causes allude to those work environment mishaps that happen considering the workspace. The ecological elements can be both normal and man-made, for example, the work environment plan. Normal natural reasons for mishaps include:

Unfortunate lighting – Low perceivability is a typical reason for slips, excursions, and falls. It is one of the top causes of accident in industry.

Surrounding temperature – Why do industrial disasters occur during summer? Often due to overheating or unmanaged ambient temperatures. Assuming that a working environment is excessively hot, overheating can happen. Assuming that the working environment is excessively cool, frostbite or hypothermia can happen.

Air contamination – Breathing issues can create if a working environment has unfortunate ventilation or potentially air contamination. It not only causes breathing issues but can contribute to long-term industrial disaster causes.

Sound contamination – The sound in a working environment can make injury a specialist’s hearing.

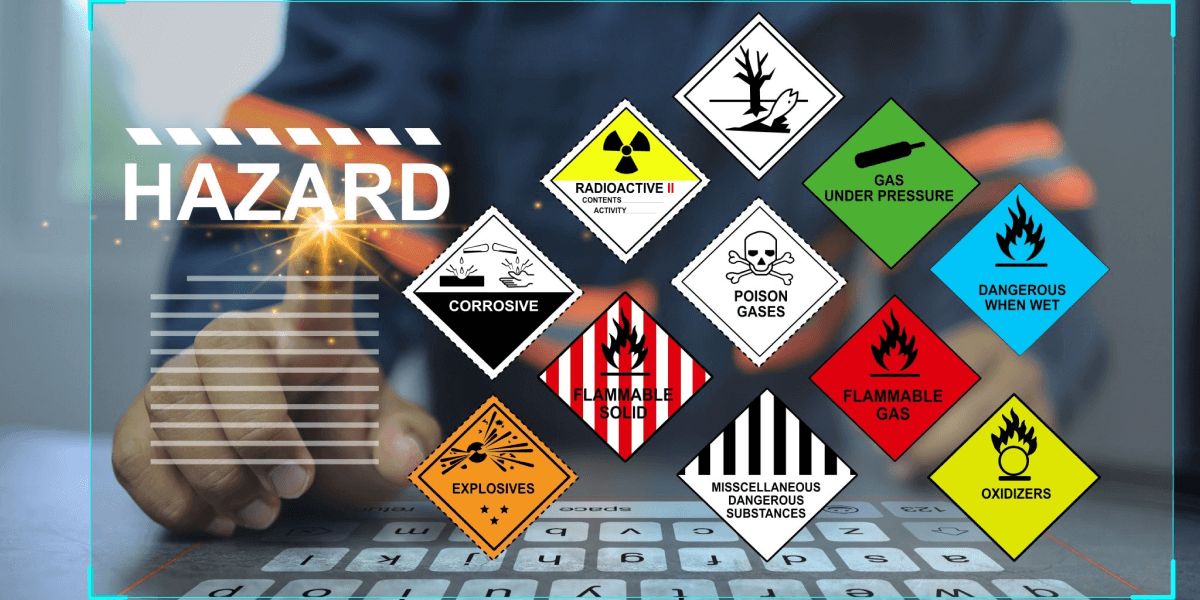

Hazardous Materials – Exposure to toxic substances or chemicals can cause long-term health effects or even fatalities if not handled properly.

Don’t let poor lighting or ventilation cause your next accident. Explore our industrial safety audits.

2. Machine-related Causes of Industrial Accidents

Mechanical reasons for modern mishaps are factors that allude to machine or gear disappointment or breakdown. For the most part, with appropriate support and safety processes set up, these kinds of mishaps are preventable. Normal mechanical reasons for mishaps include:

Broken or harmed machine – Parts can be handily broken or harmed whenever made of low-quality metal. They often top the list of causes of industrial accidents.

Power disappointment – Aggregate or halfway power disappointment can prompt genuine injury.

Fire or blast – Cooling disappointment or a little flash can prompt a mechanical fire or blast.

Fair mileage – The more established machine, the more mileage on the parts which can prompt a higher gamble of a mechanical mishap. Equipment failure is a direct answer to why do industrial disasters occur, particularly when maintenance is skipped.

Prevent breakdowns before they happen—discover TECH EHS incident management software solution.

3. Human Factors – causes of industrial disasters

Mishaps made by human variables allude to episodes in which the mishap is straightforwardly ascribed to the specialist associated with the mishap. Normal human factors that cause modern mishaps include:

Human Error – Mistakes made by workers, such as miscommunication, lack of training, or negligence, can lead to accidents.

Unfortunate housekeeping – An unkempt work area can prompt slips, excursions, and falls.

Weariness – At the point when a body is drained, injury is bound to happen.

Overexertion – Overexertion wounds are the most well-known sort of work environment injury. Fatigue and overexertion are all common causes of accident in industry.

Stress – Laborers who are focused on are in many cases more diverted and of the more serious gamble of injury.

Lack of hydration – It is essential to drink sufficient water to guarantee your body works appropriately. Stress and dehydration also increase the risk of industrial disaster causes, especially in high-pressure environments.

Inappropriate Lifting – Lower back strains and shoulder wounds are normal among laborers who utilize ill-advised lifting methods.

Train your team to prevent human errors—learn about our occupational health management software.

4. Other Causes

Young, untrained, and experienced workers are prone to accidents. Alcoholic and drug-addicted workers, those having disturbed family life, who overwork, experience monotony, fatigue, and quarreling, abuse, unsatisfactory behavior of supervisors are some of the reasons for industrial accidents.

Natural disasters like earthquakes, hurricanes, or floods can damage infrastructure, leading to accidents.

Poor Safety Culture, Lack of safety procedures, inadequate safety training, and failure to enforce safety policies can also lead to accidents.

By understanding and addressing these certain causes of industrial disasters, organizations can work towards creating a safer workplace for their employees and preventing future accidents.

Measures to Ensure Industrial Safety:

To decrease or limit the actual dangers and mishaps, safety management is important.

Particular estimates which can be taken to guarantee modern safety are:

1. Safety Engineering :

Implementing robust safety engineering practices is essential to minimize workplace accidents. Fencing of apparatus, sufficient room between machines parts and types of gear, utilization of material taking care of hardware, gadgets, appropriate upkeep of machines, and so forth, are attempted to keep mishaps from happening.

By prioritizing safety engineering, organizations can proactively address potential hazards.

Enhance your facility’s safety with our expert safety observation system.

2. Training and Education :

Regular industrial safety training sessions are crucial for educating employees about safety protocols. Preparing and instruction projects must be held now and again to prepare and teach representatives, bosses, and laborers, about insurances to be taken during machine dealing. Safety animation and training come to the rescue. These projects must be created and energized among them by proper machine maintenance, etc.

Effective industrial safety training fosters a culture of safety and awareness among workers.

Empower your workforce with our comprehensive animated safety training videos.

3. Committee on Safety :

Establishing a dedicated safety committee within the organization ensures continuous focus on safety matters. It should include representatives from both management and the workforce. The committee’s role is to provide guidance on safety measures and ensure their implementation across the facility. All safety programs and policies should be carried out through this advisory group. Additionally, the committee should organize periodic safety campaigns, workshops, and contests to promote a strong safety culture among employees.

A proactive safety committee plays a pivotal role in maintaining a safe work environment.

Learn how to set up an effective safety committee with our guidance.

4. Normal Inspection :

Conducting periodic industrial safety inspections helps identify and rectify potential hazards. There must be a customary investigation of machines and gear to actually take a look at any imperfections if any. The examination must be to likewise make sure that the machines are all around kept up with and gadgets are appropriately connected or appropriately positioned. Associations to likewise screen and assess the laborers at normal stretches to check whether they are following alerts, directions, and safeguards while taking care of any machine or hardware.

Regular industrial safety inspections are instrumental in preventing accidents and ensuring compliance.

Schedule your next industrial safety inspection with our certified experts.