Table of Contents

Introduction

scaffolding safety is an ongoing process that requires continuous attention and improvement. Staying informed about the latest safety standards and scaffold technology innovations helps keep your site as safe as possible.

When you embark on a construction project, there’s a possibility that you oversee a lot of planning and detailed research that goes into the beginning of the process – even before the actual work is begun.

So, how do you prepare for a project that requires safe scaffolding, and what is scaffolding in safety? Let us explore.

One cannot live by others’ opinions in all cases—though they should be considered, they might not always be a good catch. One should do his/her research before stepping up for a safety learning (animation) partner. While do pay attention to the reviews, there are chances that some might be just a perfect fit for you. So be a final decision-maker!

Ensure that the company you look out for possesses just what you require and…

Select them!

When do you need scaffolding?

“Build it when you need it!”

A one-man job for someone who wishes to paint a roof will sufficiently require just a ladder – anything more might be an extra. But still, an adequate assessment is needed.

But if there are tasks where you need to work from a height, such as building construction or roof repairs, you likely need to meet the health and safety standards for conducting work.

The key remains the number of people working around – if multiple people tend to stay on the job.

Basic questions that you need to ask (there can be more)–

How to Forestall Falls While Working on Scaffolding

Scaffolding safety serves the following causes –

If terrain or an area becomes too tough to work on, the access is a scaffold. If it is established and used appropriately, it is a protected platform to elevate fundamental tasks.

But because it is a part of Work at Height, dangers and risks inherently exist and one can’t step away from them.

Serious dangers or deadly accidents expand in falls, and it is viable to be struck by way of falling tools, substances, or particles that can lead to electrocution.

The site supervisor and scaffold inspector must ensure that they have a duty to ensure that the web page is in a protected area for work and that every precaution has been taken to minimize the threat of working at a height. But overall, the worker working at height must ensure they follow the scaffolding safety procedures diligently.

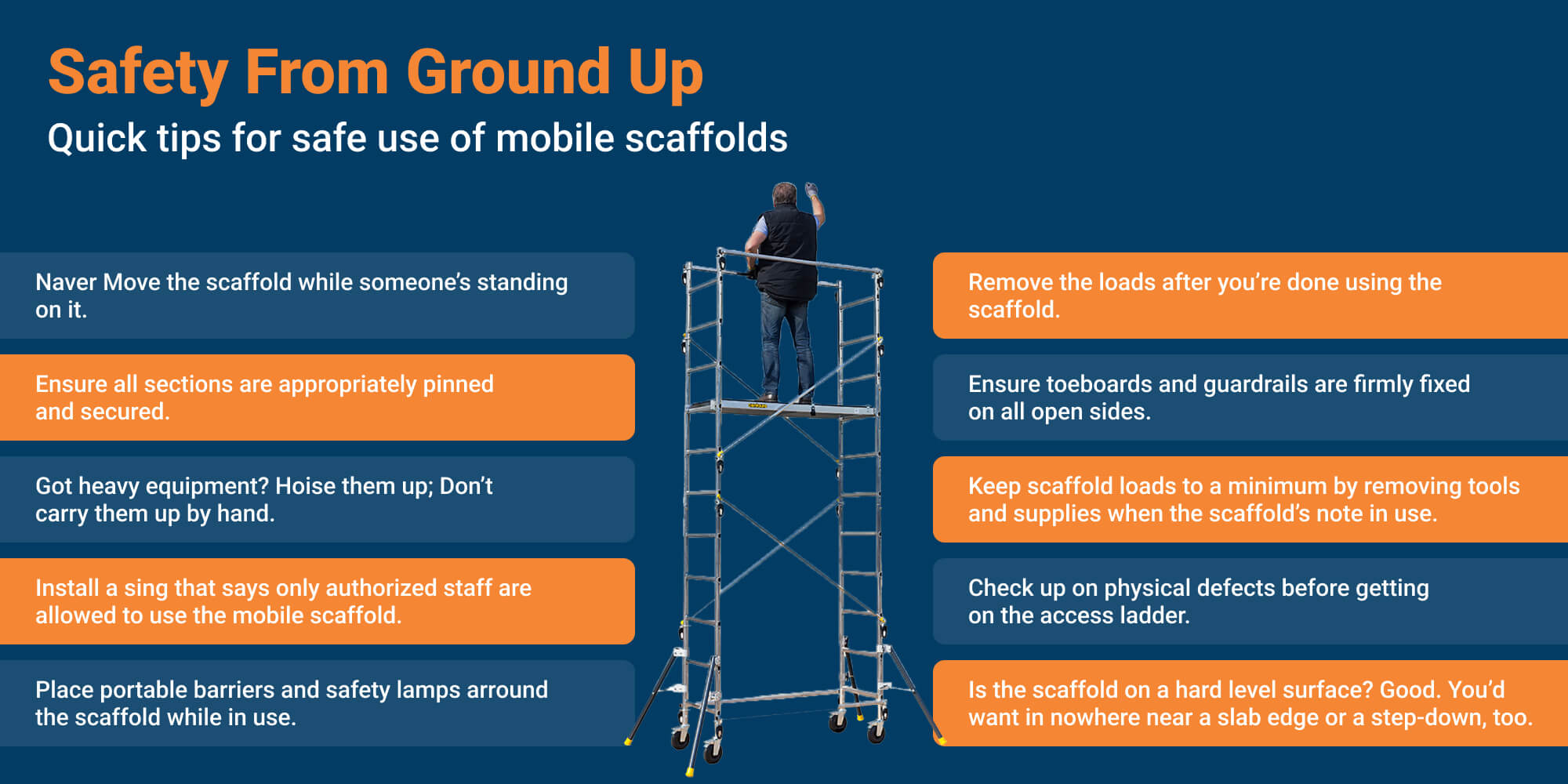

Take Control of Your Surroundings

This is finished by carrying out a complete hazard evaluation before you begin the work—this way, you become aware of the risks and what needs to be done to limit them.

If a choice approach is available or the chance is far too high, then working at peak should no longer be undertaken.

Inspect Your Scaffolding

Safe scaffolding inspections are integral and must be carried out right after the scaffolding has been erected and earlier than any work is carried out on it to ensure its safety, and then weekly thereafter. Keep scaffolding SOPs handy and updated.

An expert and thorough inspection will discover any weaknesses or risks in the structure, for example, if it isn’t properly braced or tied to the building.

It will additionally highlight any missing parts/pieces that should guard your workers, such as handrails and crash decks.

With PPE, Stay Prepared to Survive

Again, before work commences, all employees should receive extensive training, coaching, and adequate PPE for working at heights for escalated scaffold safety.

This will ensure that they are conscious of their obligations, the security measures or procedures they wish to comply with to prevent a fall or injury, and that they are appropriately trained.

It is about how to use the tools that will defend them, including helmets, harnesses, fall arrest kits, and the safe use of scaffolding.

Keep Calm and Keep It Tidy

Easy and tidy work surroundings don’t simply make working faster and easier; they can also virtually preserve employees’ and their safety.

Slips, trips, and falls ordinarily result from terrible housekeeping throughout all industries, particularly in buildings, where tools, working substances, and particles can frequently be left lying around, which offers a day-out hazard.

Encouraging worksite employees to tidy up after themselves and keep walkways clear can definitely decrease the chance of an accident. Good housekeeping is a crucial aspect of scaffolding safety requirements.

Assess Your Environment – See More, Decide Better

Weather is any other hazard that can lead to accidents, mainly sturdy winds blowing substances and particles off scaffolding and onto the floor below.

Therefore, work from a scaffold ought to be halted when an unsafe climate, such as sturdy winds, heavy rain, thunderstorms, or snow, is expected.

It is additionally frequent for those working at the top to be exposed to overhead electricity strains, which present the viable risk of electrocution.

Though this will commonly be protected in the applicable coaching that needs to be executed earlier than work begins, and the chance will be recognized in any hazard evaluation that takes place, it will want to be without a doubt communicated to the employee so that they are conscious of these practicable risks themselves.

Never Cut Corners from Essentials.

Above all, when it comes to virtual training (eLearning), equipment, and inspections—something we have cited—the essential element is that you take the time and care to make sure that it is all accomplished properly.

Don’t try to save money by using low-cost PPE that is also less advantageous.

Don’t attempt to rush matters by skipping the inspection so you can get straight to work. This is where errors are made and employees are put in danger.

Never sacrifice site protection for speed, comfort, or price. Usually, take the time to be as thorough as possible, even if it delays the work. There are other ways to ensure speed and efficiency.

The protection of your employees and visitors is the most vital phase of your job, so seeking the recommendation and aid of an expert group is crucial and beneficial in preventing falls and accidents.

Businesses can reduce hazards while operating by providing employees with the right health and safety training. The following advantages accrue to employers who devote time and money to workplace health and safety training:

Providing personnel with appropriate HSE training has several benefits for firms.

Conclusion

Scaffolding safety is critical to construction site management, requiring diligent planning, constant vigilance, and adherence to best practices and regulations.

As site managers, your role in ensuring the safety of workers on scaffolds cannot be overstated. The guidelines and strategies detailed in this guide provide a comprehensive framework for maintaining a safe scaffolding environment.

However, the truth is that scaffolding operations’ safety is a collective responsibility that starts with effective management. By prioritizing safety and fostering a culture of vigilance and continuous improvement, you can ensure that every project is completed without incident, safeguarding the lives and livelihoods of your workforce.