Table of Contents

Introduction

Manufacturing safety hazards are multifaceted, ranging from physical dangers posed by machinery and materials to ergonomic and environmental risks. Despite advances in safety protocols and technologies, the industry faces significant challenges in mitigating these dangers. Understanding the most common and critical safety hazards in the manufacturing industry is essential for developing effective prevention and response strategies.

With the advent of new technologies, manufacturing safety is set to improve efficiency, quality of work, and employee safety. It is growing from strength to strength, developing capabilities from real-time equipment maintenance to virtual design and opening a scope of possible applications.

Safety in the manufacturing industry has become an essential differentiator in these industries – all share and communicate a joint commitment to providing a workplace that has constituted and implemented an up-to-date risk and hazard management plan. Factory environments pose visible dangers, making adherence to factory safety rules essential. Safe and healthy workplaces are an asset to a business, which helps it operate more efficiently, and companies can enjoy a healthy bottom line.

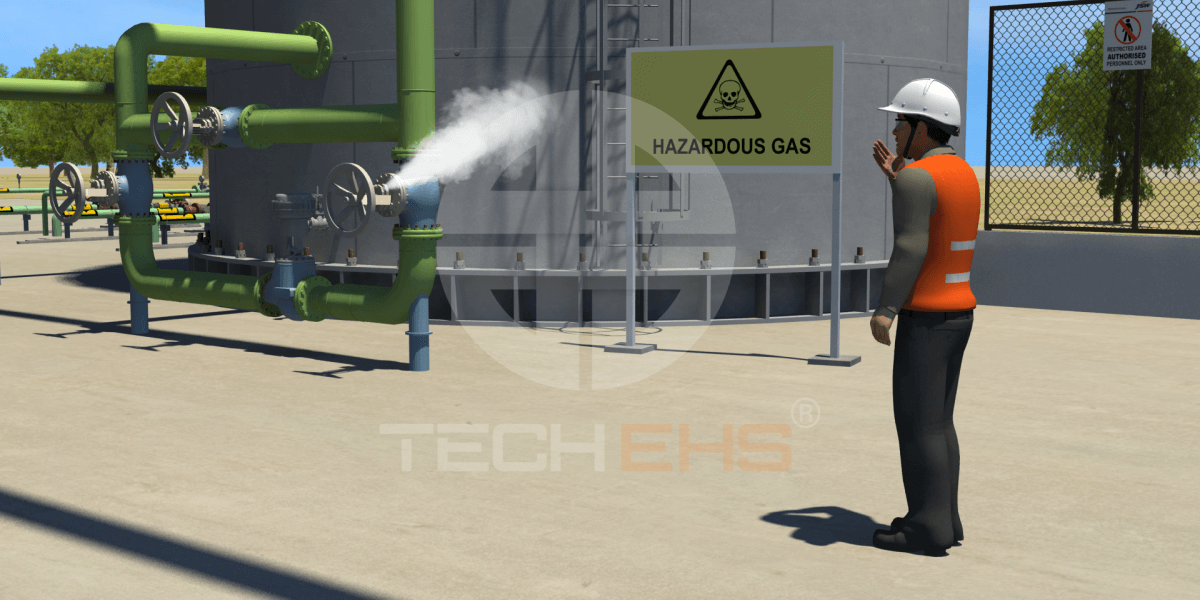

Once you identify the most common safety hazards in the manufacturing industry, preventive measures become easier to implement. TECH EHS safety animation aims to address critical health and safety issues in the manufacturing industry to allow a better understanding of their significance in safety.

Safety Hazards In The Manufacturing Industry

Fall From Heights

Fall protection violations remain on top of the list of safety violations in the year 2019 – 6010 violations were reported[1]. Even a fall from six feet can prove deadly when landing on the wrong body part or surface. Spinal, head, or neck injuries are common, regardless of height, and can leave a worker severely disabled or fatal. An informed choice of equipment and knowledge can safeguard workers from potential falls—proper PPE, comprehensive training, and adherence to factory safety rules can help safeguard workers from falls.

Electrical safety

Among the significant safety hazards in the manufacturing industry, electrical risks are hazardous. Common electrical manufacturing hazards that put industrial workers at risk are overhead powerhead lines, damaged tools and equipment, improper grounding and exposure to electrical parts, damaged insulations, and wet conditions. Identifying and mitigating these manufacturing safety risks through training and best practices ensures compliance with safety in the industry standards.

TECH EHS animated movie provides guidance on proper electrical safety measures to help minimize health and safety issues in the manufacturing industry.

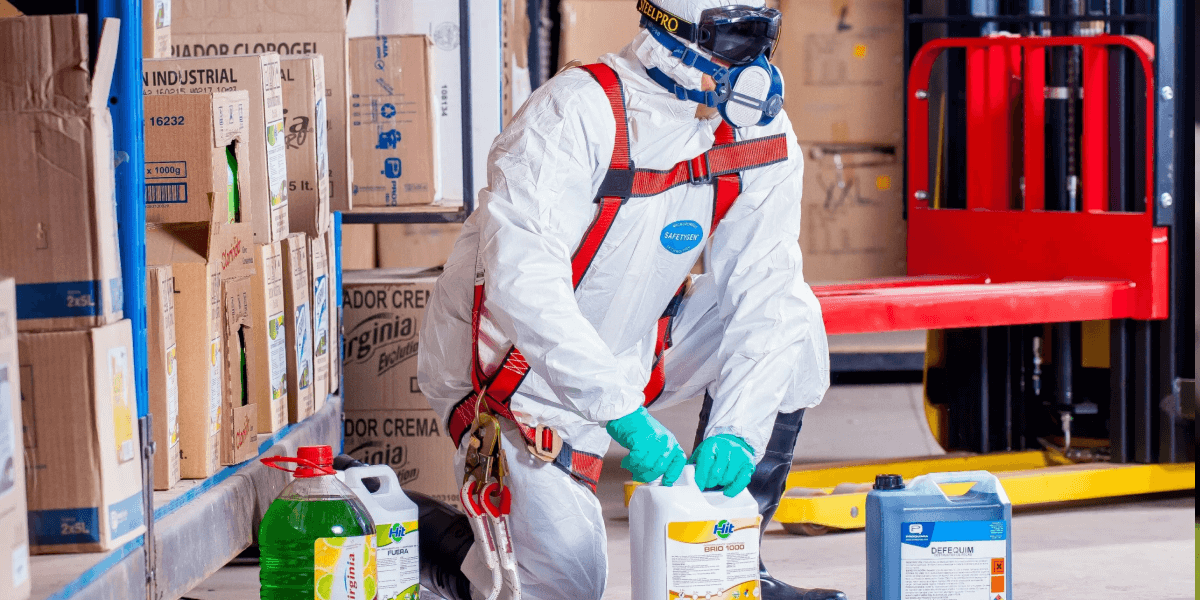

Lockout Tagout-Tryout (LOTOTO)

LOTOTO has been considered one of the safest methods of isolating equipment prior to its repair and maintenance. Its main purpose is to protect employees from accidental re-energization of equipment that has the potential to cause injuries or fatalities. As this is imperative in ensuring a safe lockout, proper training and adherence to factory safety rules are essential for effective implementation.

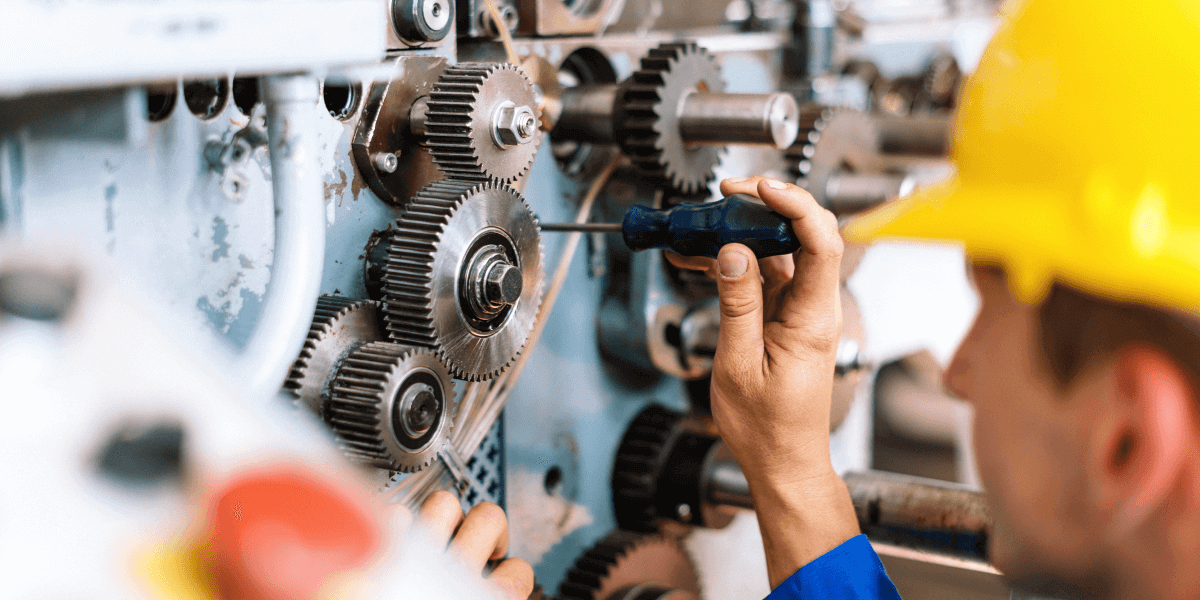

Machine Guarding

OSHA statistics claim that workers who operate and maintain machinery suffer approximately 18,000 amputations, lacerations, crushing injuries, abrasions, and over 800 deaths per year. Poor guarding is one of the most overlooked safety hazards in the manufacturing industry. Hence, guarding workers against hazards caused by moving parts within the equipment or machines enhances manufacturing safety and reduces workplace risks.

Powered Industrial vehicles (PIVs)

Known as forklifts, power jacks, lift trucks, and reach trucks, these are the most common vehicles seen on worksites, often used to raise, lower, or remove small and large objects on pallets or in boxes, crates, or other containers. Incidents involving PIVs that result in injuries and damage to public property are primarily due to a lack of training or working within an instruction-based environment. Workers who neglect factory safety rules or take shortcuts around protocols increase accident risks. Practical training and awareness of surroundings can significantly improve safety in the manufacturing industry.

Conclusion

TECH EHS safety animation can help you create awareness of safety hazards in the manufacturing industry. Remember, preventive steps for all the above hazards and escalating health and safety in manufacturing consume a little extra time—regular inspections, effective training, or appropriate PPEs. However, that extra time can avert a potential incident and prevent an on-site worker from experiencing painful downtime. Prioritizing manufacturing safety and implementing robust factory safety rules ensures a safer, more productive work environment.

So now, if it is to be noticed what are two common workplace hazards within the manufacturing sector? We know that there are not two but five or more things that the manufacturing sector needs to be safe of!

References:

1. OSHA Reveals Top 10 Violations for 2019 at NSC Congress and Expo: National Safety Council, published September 2019, accessed on 21 Jan 2020. Find online here.