Table of Contents

- Introduction

- Warning signs that point towards PTW system failure

- Inefficient Permit Preparation Timing

- Inadequate Hazard Coverage

- Lack of Automated Permit Procedure and Workflow

- Inability to Easily Copy and Adapt Permits

- Legibility Issues with Permits

- Permits’ Failure to Address Simultaneous Operations (SIMOPs)

- Insufficient Inspection Before & After Permit Signing

- Non-compliance with Permit Requirements by Workers

- Lack of Enforcement and Audit of the Permit-to-Work Process.

- Complex or Non-User-Friendly Permit System

- Toolbox Talks Not Integrated with Permit Issuing Process.

- Conclusion

- Frequently Asked Questions(FAQ)

Introduction

The efficacy of Permit-to-Work (PTW) systems is critical for maintaining safety in high-risk environments. However, these systems often fall short due to various factors. A closer look at common PTW failures reveals a pattern: gaps in implementation, training, communication, and organizational culture can undermine the safety they are designed to ensure.

Picture this: a workplace accident so catastrophic it makes Chernobyl look like a small kitchen fire. One can only imagine the massive magnitude of the outcomes.

The cause? A faulty permit-to-work system.

An airtight permit-to-work system ensures safety at work. A lack of one can lead to devastating events.

However, it is worth noting that significant workplace accidents are frequently attributed to the failure of permit-to-work (PTW) systems, as evidenced by accident data from the U.S. Chemical Safety and Hazard Investigation Board (CSB), case studies, and best practices established by the Center for Chemical Process Safety (CCPS).

It’s the nightmare scenario that keeps every safety manager up at night. Not only does it result in a loss of time and materials, but it can also cost workers their lives. So, what’s causing these permit-to-work systems to fail so miserably?

Let’s dive deeper into these murky waters of PTW acquisition to find the truth.

But it is easier said than done. Implementing metro projects faces challenges right from the beginning and continues until their maintenance. If addressed proactively, these challenges will not pose intense threats. Let us see which of the following are challenges for metro construction.

Warning signs that point towards PTW system failure

Inefficient Permit Preparation Timing

Considering how crucial work permits are, it is essential to ensure they are prepared at the right time. One common reason permits fail is that they are either prepared too far in advance or after the work has already begun.

When permits are prepared too far in advance, it can cause delays and unnecessary expenses, as they may expire before the construction work starts. Conversely, when permits are prepared after the work has already begun, it can result in significant legal and financial consequences.

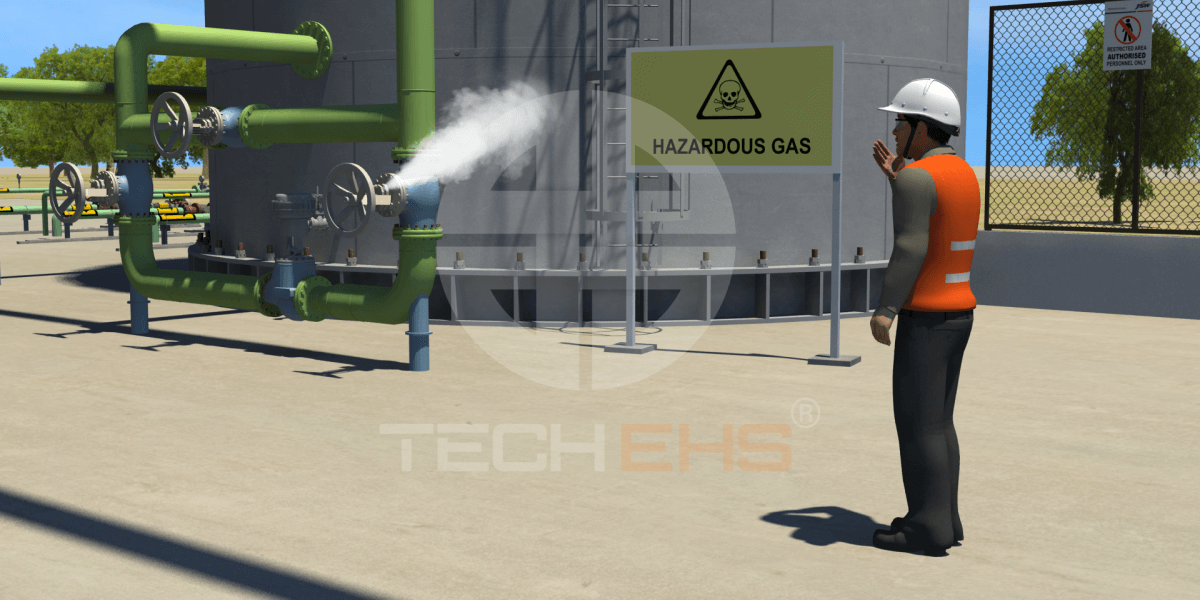

Inadequate Hazard Coverage

At times, there may be gaps or limitations in the scope of a particular permit. This could mean that the permit is not comprehensive enough to address all of the potential hazards that may arise in a given situation. It could also indicate that the permit’s format is not suitable for capturing all of the potential risks that need to be considered.

Given this, careful planning and thorough risk assessment are essential to ensure that all hazards are identified and addressed appropriately.

Lack of Automated Permit Procedure and Workflow

With a manual and paper-based permit system, there is a gap in streamlining the request, creation, approval, and issuing of work permits. This lack of automation points towards a slower permit process that may be more prone to errors. This would lead to delays and give rise to safety issues.

An automated permit procedure and workflow can also help thaw the complex and time-consuming process for stakeholders involved in the permit process, including requesters, approvers, and issuers. To address these challenges, implementing an automated permit process can help to improve efficiency, accuracy, and safety in permit management.

Inability to Easily Copy and Adapt Permits

Creating a new permit is time-consuming and cannot be expedited by duplicating and adapting an existing permit. This means that every time a new permit is required, the process must start from scratch, and no time-saving shortcuts can be taken. This can be an inefficient use of time, particularly when permits need to be created frequently.

Without the ability to copy and adapt existing permits, permit creators may need to input the same information repeatedly, leading to potential errors and inconsistencies. To address this challenge, implementing a permit management system that allows for the duplication and adaptation of existing permits can help to save time and streamline the process of creating new permits.

Legibility Issues with Permits

Some permits may have clarity and readability issues, making it difficult for stakeholders to understand and follow the permit’s requirements. This can result in confusion, misinterpretation, and errors, compromising safety and increasing the risk of accidents. In some cases, permits may contain important information critical to the safe execution of a task, such as technical specifications, instructions, and safety guidelines. If this information is hard to read and understand, it may be overlooked or ignored, resulting in unsafe practices.

To address these challenges, it’s essential to ensure that permits are designed using clear fonts, appropriate font sizes, and contrasting colors to make the information more visible and easy to read. In addition, electronic permits that use digital signatures can also help improve legibility and ensure the permit is valid and enforceable.

Permits’ Failure to Address Simultaneous Operations (SIMOPs)

SIMOPs occur when two or more operations take place simultaneously in the same work area, which can increase the likelihood of accidents and injuries. However, some permits may not consider the additional risks that arise from SIMOPs, which can result in incomplete hazard identification and risk assessment.

To mitigate these risks, it’s vital to ensure that permits explicitly address SIMOPs and include appropriate controls and measures to ensure that all operations can be performed safely and without interference. This includes work area separation, communication protocols, and emergency contingency plans.

Insufficient Inspection Before & After Permit Signing

In some cases, the person responsible for signing a permit may not have personally inspected the work area or confirmed that all necessary isolation, lockout, or testing procedures have been completed before & after issuing the permit. This can lead to unsafe conditions, as the permit may be issued without a thorough understanding of the risks and hazards associated with the operation.

To ensure that permits are issued responsibly, it’s crucial to implement a robust approval process that includes a thorough inspection of the work area and confirmation that all necessary safety measures have been taken before the permit is issued.

Non-compliance with Permit Requirements by Workers

Lack of understanding of the permit requirements among workers may lead to unsafe practices and increase the risk of accidents and injuries. Workers may not follow the permit’s requirements due to a lack of understanding or training or intentionally deviate from the permit to complete work more quickly.

Ensuring that workers are adequately trained on the permit requirements and understand the importance of following them is crucial. This can include providing clear and concise instructions, conducting regular training sessions, and enforcing consequences for noncompliance.

In addition, supervisors should monitor the work area to ensure that workers follow the permit requirements and address any deviations immediately to prevent unsafe practices.

Lack of Enforcement and Audit of the Permit-to-Work Process.

When the permit-to-work process is not enforced or audited, it can lead to inconsistent application of the permit requirements, noncompliance, and an increased risk of accidents and injuries. Without oversight, it can be challenging to identify and address issues with the permit-to-work system, such as incomplete or inaccurate risk assessments, inadequate controls, or insufficient training.

Regular inspections and audits, documentation of permit approvals and rejections, and consequences for noncompliance or failure to follow the permit requirements need to be implemented. Organizations can mitigate risks and ensure the safety of workers and the surrounding environment by prioritizing enforcement and audit of the permit-to-work process.

Complex or Non-User-Friendly Permit System

When the permit system is too complex or not user-friendly and intuitive, it can lead to frustration, confusion, and errors. Workers may need help understanding the permit requirements, completing the necessary steps, or accessing the system. This can result in work delays, non-compliance, and an increased risk of accidents and injuries.

To address these challenges, it’s essential to design the permit system with the end-users in mind and prioritize simplicity, clarity and ease of use. This can include simplifying the steps required to obtain and approve permits, providing clear instructions and guidance, and ensuring the system is accessible and user-friendly for all workers. By prioritizing a user-friendly permit system, organizations can increase compliance, improve efficiency, and reduce the risk of accidents and injuries.

Toolbox Talks Not Integrated with Permit Issuing Process.

Toolbox talks are essential to the safety management system and are intended to provide workers with information on performing their work safely. When toolbox talks are not managed as part of the permit-issuing process, workers may not be aware of the hazards associated with their work. They may not take the necessary precautions to mitigate those hazards. This leads to a lack of communication and understanding among workers.

Integrating toolbox talks into the permit-issuing process ensures that all workers have received the necessary information and training to perform their work safely. This can include incorporating toolbox talks into the permit application process, requiring workers to attend toolbox talks before beginning work, and documenting the completion of toolbox talks as part of the permit approval process.

Conclusion

The efficacy of Permit-to-Work (PTW) systems is critical for maintaining safety in high-risk environments. However, these systems often fall short due to various factors. A closer look at common PTW failures reveals a pattern: gaps in implementation, training, communication, and organizational culture can undermine the safety they are designed to ensure.

A PTW software can ensure that the PTW processes are maintained and implemented right from the start.