Table of Contents

Introduction

A digital PTW system can be a very effective option for almost all industries where permits are raised regularly. A digital platform provides many benefits to corporations, both in operations and in providing valuable information—all this while being proactively safe.

Digitalization is the need of the hour. But what actually does digitalization mean?

Let’s clarify: Digitalization does not mean eradicating humans from the process. It means helping humans to eliminate errors and improve the process. It also decreases the workload and automates and escalates work processes, leaving more room for productivity.

So how does digitalization help in work permit digitalization?

The PTW process is designed and managed to safely execute any activity or task. With changing times and tides, digital technology is considered one of the best platforms for automating routine processes (like PTW systems).

Therefore, a digital PTW system can be a very effective option for almost all industries where permits are raised regularly. A digital platform provides many benefits to corporations, both in operations and in providing valuable information—all this while being proactively safe.

Let us explore the electronic permit-to-work system in brief.

The Electronic Permit to Work System

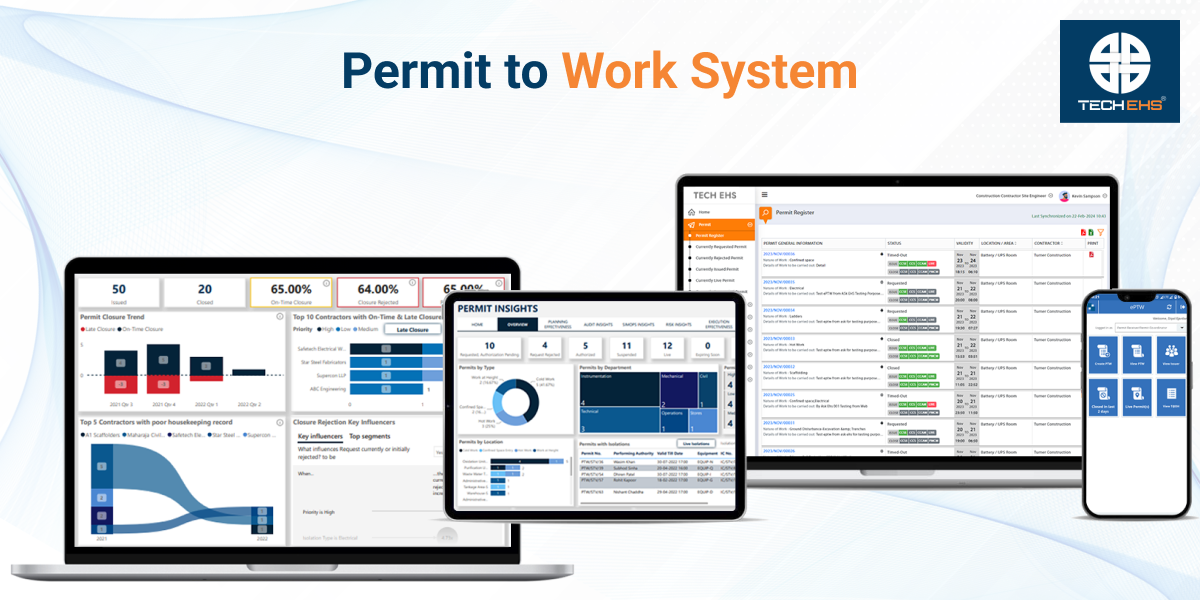

A digital Permit-to-Work solution revolutionizes permit lifecycle management. It seamlessly synchronizes operational, maintenance, shutdown, project, and other scheduled or unscheduled work, thereby enhancing operational efficiency, productivity, and safety compliance.

The system can integrate with existing ERP systems to synchronize all related work easily. This helps collect and display data from different supporting activities and consolidate it. The digital permit-to-work system plays a crucial role in risk management. With it, organizations can seamlessly manage changing floor operations while averting potential hazards.

Even if you are worried about shift handovers, the electronic permit-to-work system manages a standardized procedure. Also, other features include;

The above features of the e-PTW system not only improve the PTW processes but also amplify safety processes. This proactive safety management ensures minimal or no incidents.

Now that you are aware of the features, let us discuss the benefits of permit to work system.

Benefits of Digital Permit to Work

If the above features are not enough to convince you, here are five great benefits of electronic permit to work.

Convenience in carrying out a PTW process

Permit to work digitalization makes it convenient to carry out the PTW issuance process.

For instance,

Digitalization – the Need of the Hour

An automated, ‘web-based’ application saves time and resources and enhances transparency in managing and monitoring the PTW process.

Time status of any work certainly gives an edge to decision-makers.

A Consistent and Uniform Permit Issuance Process

Companies that have various plants/facilities spread across vast geographies might be following different PTW processes. Standardization of the PTW system can be a huge logistical and systemic challenge. A digital permit-to-work system can be one of the primary solutions.

A digital system helps in designing and maintaining all the

that are being followed for carrying out the work activity accurately, safely, and efficiently. Any change in any of the standards of a work permit can be done through a central control center electronically.

A Digital PTW System for Operational Effectiveness

A digital PTW system brings along excellence in operational effectiveness for organizations as it;

MIS and KPIs

For companies with plants/facilities worldwide, getting regular updates and/or reports about work permits can be a huge challenge. Control centers in corporate offices might want reports about permits that are in circulation. Similarly, preparing such reports for individual plants might be tedious. Preparing such reports manually might be prone to human errors and inaccuracies.

A digitally enabled PTW system can provide accurate information at a simple button click. Predictive analytics, Insightful trends, Statistical graphs and charts, etc., are part of any digital ecosystem. Companies can benefit from such “real-time” and “click-ready” reports for better decision-making.

Conclusion

Implementing an e-ptw system offers several hidden benefits that can significantly enhance safety, efficiency, and overall operational excellence. We all know that permit processing includes complex processes. And to streamline these processes is another crucial task. All the PTW processes can be simplified and improvised with a digital permit to work system.