Table of Contents

Introduction

Cutting, welding, brazing, soldering, grinding, drilling, chipping, blasting, heat-treating, defrosting pipes, applying roof coatings, and repairing tar pots and kettles are all examples of hot work processes.

How does safety in a hot work process matter in a large-scale industrial facility?

Let’s find out!

Numerous unanswered concerns regarding the horrific hot work incident remain nearly 14 months after the explosion in the Port of Beirut, but one thing is sure: hot work served as the spark that ignited the epic series of events. More than 70,000 units were affected, 218 people died, more than 7,000 people were hurt, and at least 300,000 people had to hunt for accommodation as a result.

According to the World Bank, a single spark caused between 3.8 and 4.6 billion dollars of destruction.

Lebanese officials’ hangar 12 in the Beirut port had a broken door and a hole in the external wall that needed to be fixed on August 8.

Their hot work process produced sparks that ignited the neighbouring fireworks supply and caused the ammonium nitrate to explode in a way that stunned the entire world.

Even though an uncommon hot work incident of that size presents an intriguing case study for the NFPA Fire & Life Safety Ecosystem, the hot work incident and its aftermath demonstrate that hot scenarios can have some very serious, expensive, and tragic consequences.

What is hot work in safety?

Cutting, welding, brazing, soldering, grinding, drilling, chipping, blasting, heat-treating, defrosting pipes, applying roof coatings, and repairing tar pots and kettles are all examples of hot work processes.

According to NFPA research, 4,580 hot work-related structure fires are estimated to occur annually in the United States alone, with non-residential locations accounting for 57% of incidents.

The human cost is in addition to the accompanying expenses for property destruction, business continuity, and displaced residents.

It would seem evident that working with fire close to flammable or combustible objects is dangerous. Materials that ignite easily don’t play well with fire. Why do we keep reading or hearing stories about flames or explosions caused by hot work processes?

Does your hot work procedure address flammable dust, by the way?

Hot work is a significant contributor to industrial work processing fires year after year, resulting in numerous injuries, fatalities, and large property losses. It’s similar to welding or cutting with an oxy-acetylene torch, but much more.

Any task that has the potential to generate enough heat to start a fire or explosion is considered hot work.

Did you know that high-speed metal grinding and cutting are included in hot work?

Any activity using an open flame, such as brazing, heating, burning, and soldering with an open flame torch, is hot work.

Even though personnel are aware of combustible materials in the vicinity, they may not know where these elements may build to dangerous amounts and can result in an explosion or flash fire.

Does your hot work hazards communication program indicate the physical risk of your combustible dust if you have it?

Accidents at hot workplaces are avoidable.

“We were able to stop the welding operation before things got hot,” turning this incident into a near-miss. This statement is a long-awaited one, of course!

There is a lot left out of this. Training and performing activities with safety animation and eLearning involving heated work, cramped areas, and dangerous materials, including combustible dust, is vital.

Hot work, also known as the use of open flames and spark generators, is one of the main causes of fires and explosions.

Hot work techniques include cutting, welding, thawing pipes, torch-applied roofing, and soldering. Despite the risks, hot work is a crucial component of many enterprises.

Hot Work Processes Safety Advice

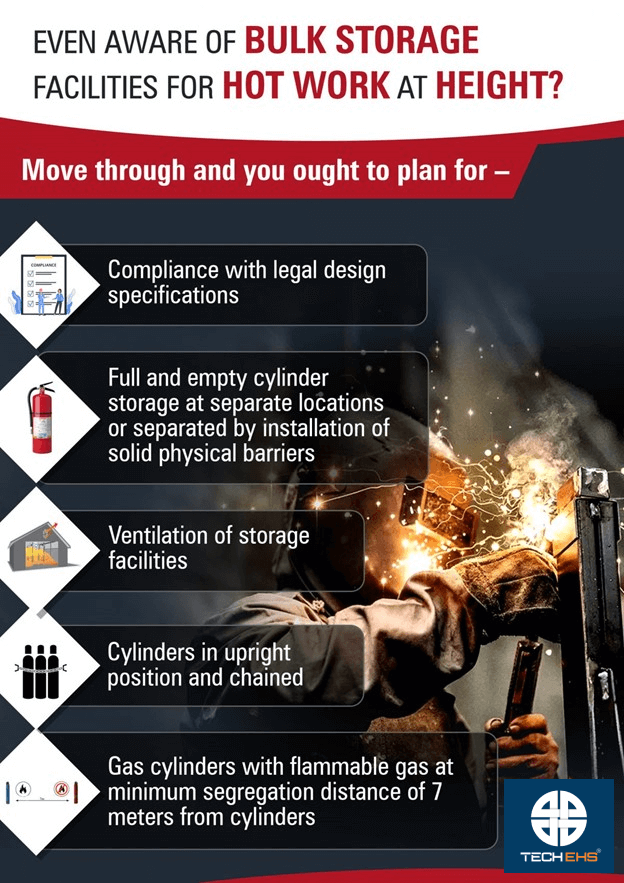

Your company must establish a clear policy to encourage hot work safety to avoid property damage and employee injuries. It’s ideal to complete hot work within regular business hours.

Hot work hazards and precautions must form a crucial part of your training program. Following some safety advice absolutely does no harm—have a look:

Find out if the institution has a hot work management program in place before performing hot work there. Document everything you do while doing the job, and make sure your client approves and signs off on it. Any off-site business can benefit from the above-mentioned on-site safety advice.

Finally, double-check the details of your insurance policy, particularly the liability protection for heated labour.

Tell us more about your company so we can start creating a customized animation breakthrough for you so you can keep doing the hot work!