Table of Contents

- Introduction

- Why Traditional SOPs Are Failing Modern Pharma Operations

- SOPs Are Too Complex for the Floor

- Language and Literacy Gaps Widen the Risk

- Shift Handovers Are a Mess

- You Have Proof of Training But Not Proof of Understanding

- Training Happens Once—But Errors Happen Daily

- Final Word

- Frequently Asked Questions(FAQ)

Introduction

Why Traditional SOPs Are Failing Modern Pharma Operations

Pharma EHS communication is a battleground. You must contend with complex Standard Operating Procedures (SOPs), a high staff turnover rate, and regulatory pressures. In the midst of all of this, you must ensure complete safety compliance, zero incidents, and an informed staff.

Sounds familiar?

If you’ve been in such situations, you know that the issue isn’t a lack of information. It’s about reaching the right people, at the right time, and in the right way.

Here are the top 5 challenges we see in pharmaceutical EHS communication. Let’s also discuss how animated videos can fix them quickly.

SOPs Are Too Complex for the Floor

Consider Clean-In-Place (CIP) as an example. The SOP document is 30 pages long and includes control limits. It also references the PLC batch sequence. Can a new operator, however, truly comprehend how each step impacts product safety? Most likely not.

Your microbial kill step is put at risk if you miss one hold time at 80°C.

Why this happens: Static SOPs are hard to visualize. People skim through, retention drops, and missteps happen.

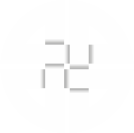

Animated fix: The “why” behind each step is made evident using 3D SOP walkthroughs. These 3D solutions replicate the real procedure and show images of tanks, valves, sensors, and hold times. Operators see the sequence and comprehend the consequences rather than merely reading it.

Language and Literacy Gaps Widen the Risk

This is something we don’t discuss enough. Not all operators on your shop floor can read English, particularly when it comes to technical words like “bioburden load” or “differential pressure.”

Imagine that at a site, operators are getting ready for Grade B. However, they miss essential steps, not because they are lazy, but because they are confused.

Why this happens: The combination of technical language and multilingual teams creates a communication gap that is just waiting to become a deviation.

Animated fix: Workers understand better when you use simple images with little language, such as airflow models, cleanroom zoning, and gowning routines. It isn’t necessary to speak fluent English to comprehend animated hints.

3D animation solutions standardize safety instructions globally. They make SOPs work across languages and roles.

Shift Handovers Are a Mess

During the shift transition from night to morning, it is observed that the incoming morning shift enters the area without being fully briefed on the operational status. The night shift fails to communicate the reactor’s condition, and it remains uncertain whether the reactor is isolated correctly. A Lockout/Tagout (LOTO) device may still be in place. When you think it’s safe, a near-miss or worse occurs.

Why this happens: Hazard flags, isolation logs, and permit-to-work updates don’t always smoothly transition between shifts.

Animated fix: Kiosks or tablets can be used to display dashboard-linked images or brief shift review movies. It indicates what is under maintenance, what has been closed out, and any remaining hazards. Everyone is on the same page at the beginning. Operators report that shift handovers are linked to approximately 40% of plant incidents, according to a NPRA industry review. This highlights the need for more precise and more consistent handovers.

You Have Proof of Training But Not Proof of Understanding

Although you have training logs in place, do they prove your operators understood what they were taught? Can you demonstrate to the FDA that each operator knows how to manage cytotoxic waste? Or how should a Class II BSC alarm be handled?

Why this happens: Signatures do not imply understanding. Do you still track it using Excel? You’re using safety compliance as a gamble.

Animated fix: Add quizzes, track scores, and upload your animations to an approved learning management system. You now have precise knowledge of who saw what, when, and how they performed.

Many pharma teams are now moving away from clipboards and spreadsheets. They are transitioning to digital audit trails and dashboards that offer real-time visibility and enhanced inspection readiness.

Training Happens Once—But Errors Happen Daily

Showing someone how to choose the appropriate gloves during onboarding is one thing. Six months later, expecting them to recall it quickly is another matter entirely. Reminders are necessary at the workplace.

Why this happens: Training once a year isn’t sufficient. Furthermore, wall-mounted laminated posters are insufficient.

Animated fix: Staff members must be reminded just before the task with brief, 1-2-minute animations shown on tablets or info screens. Simple, targeted messages such as “Don’t mix acid with oxidizer” or “Here’s how to set up the BSC” help reinforce correct procedures at the point of use.

Microlearning interventions are quick, engaging, and effective. According to Forrester (2022), implementing microlearning in this way can reduce repeat safety infractions by up to 48% within six months.

Final Word

Ultimately, the effectiveness of SOPs, regulations, and protocols depends on workers’ ability to remember and adhere to them. The stakes are significant in the pharmaceutical industry. A batch, an audit, or even a life can be lost due to a single misunderstanding.

Videos with animation are more than simply a fad. They are a valuable, technical instrument that improves the clarity, speed, and audit-readiness of EHS communication.

Create engaging animation modules specifically for your pharmaceutical plant. Incorporate your Standard Operating Procedures (SOPs), risk controls, and shift handovers. Pharma, API, and sterile facilities trust EHS compliance-grade safety animation tools.