Table of Contents

- Introduction

- Warning signs that point towards PTW system failure

- Inefficient Permit Preparation Timing

- Inadequate Hazard Coverage

- Lack of Automated Permit Procedure and Workflow

- Inability to Easily Copy and Adapt Permits

- Legibility Issues with Permits

- Permits’ Failure to Address Simultaneous Operations (SIMOPs)

- Insufficient Inspection Before & After Permit Signing

- Non-compliance with Permit Requirements by Workers

- Lack of Enforcement and Audit of the Permit-to-Work Process.

- Complex or Non-User-Friendly Permit System

- Toolbox Talks Not Integrated with Permit Issuing Process.

- Conclusion

- Frequently Asked Questions(FAQ)

Introduction

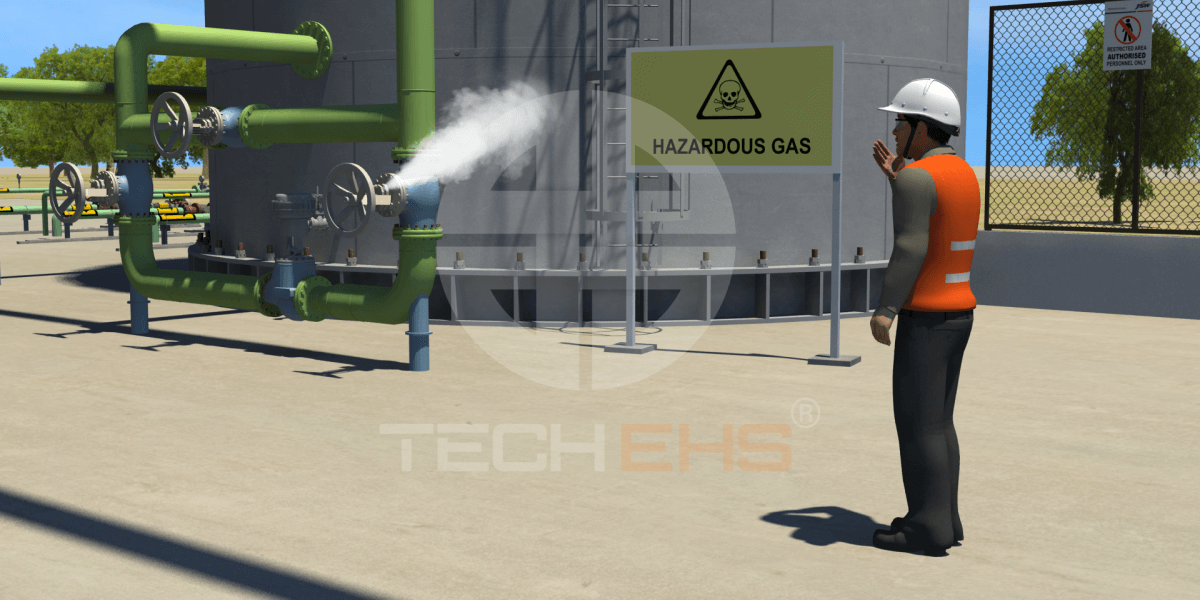

The importance of Permit-to-Work (PTW) systems is critical for maintaining safety in high-risk environments. However, these systems often fall short due to various factors. A closer look at common permit-to-work procedure failures reveals a pattern: gaps in implementation, training, communication, and organizational culture can undermine the safety they are designed to ensure.

Picture this: a workplace accident so catastrophic it makes Chernobyl look like a small kitchen fire. One can only imagine the massive magnitude of the outcomes.

The cause? A broken permit-to-work management system!

An airtight permit-to-work system ensures a safe work environment. A lack of one can lead to devastating events!

However, it is worth noting that significant workplace accidents are frequently attributed to the failure of permit-to-work (PTW) systems, as evidenced by accident data from the U.S. Chemical Safety and Hazard Investigation Board (CSB), case studies, and best practices established by the Center for Chemical Process Safety (CCPS).

It’s the nightmare scenario that keeps every safety manager up at night. Not only does it result in a loss of time and materials, but it can also cost workers their lives. So, what’s causing these permit-to-work systems to fail so miserably?

Let’s dive deeper into these murky waters of PTW acquisition to find the truth.

But it is easier said than done. Implementing projects faces challenges right from the beginning and continues until their maintenance. If addressed proactively, these challenges will not pose intense threats.

Understanding the importance of a permit-to-work system is crucial, particularly in large-scale infrastructure projects such as metro construction. Without a proper permit-to-work management system, even routine tasks can spiral into safety liabilities. Let us see which of the following are challenges for metro construction.

Warning signs that point towards PTW system failure

Conclusion

The efficacy of Permit-to-Work (PTW) systems is critical for maintaining safety in high-risk environments. However, these systems often fall short due to various factors. A closer look at common PTW failures reveals a pattern: gaps in implementation, training, communication, and organizational culture can undermine the safety they are designed to ensure.

A PTW software can ensure that the PTW processes are maintained and implemented right from the start.